- The installation of double-boom rock drilling rigs in Wuxin tunnel overcomes various difficulties in construction

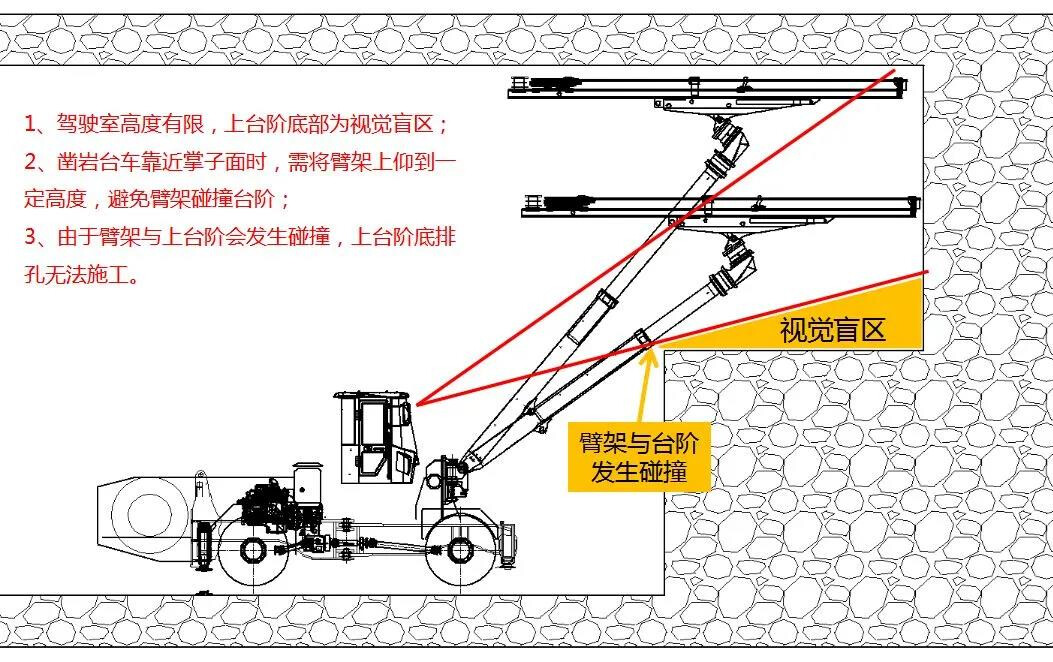

In recent years, the mechanized construction of tunnels has strongly promoted the technical progress of the New Austrian Method, but the current rock drilling rig operation still has disadvantages such as difficulty in process conversion under different geological conditions, and poor adaptability to the bench method in weak surrounding rock. , The advantage of large footage is difficult to fully utilize.

Construction problems of step method with general rock drilling rigs

Wuxin double-boom rock drilling rig construction scene

In order to solve the mechanized operation problem of step method construction, Wuxin Tunnel Installation took the lead in launching the first independently developed double-boom rock drilling rig in China in June 2021, which has a wide range of operations, wide adaptability of construction methods, high construction efficiency, and effective control. The advantages of over-under-excavation and other advantages are another major breakthrough in the field of tunnel mechanization construction.

Main technical features

Almighty: The domestic first crank arm frame structure can meet the step method construction, especially for the two-step and three-step construction, which can meet the upper, middle and lower steps.

Efficient: The scope of operation is large, one-time positioning, high-speed rail or high-speed full-section construction can be completed without moving the vehicle.

Flexible: The curved arm structure effectively avoids the collision between the boom and the steps; the length of the whole vehicle is short, and it is flexible and easy to pass through the trestle.

Intelligent: remote control operation, simple and easy to learn, can quickly get started, observe the drilling situation at close range, and effectively control over and under excavation.

Structure and construction introduction

The crank arm rock drilling rig is mainly composed of a chassis system, a hydraulic system, an electrical system, a water supply system, a gas supply system, a remote control operating system, a cab, a drill boom, a propulsion beam, and a hydraulic rock drill.

Construction process: (1) Move the machine to the operating position and prop up the front and rear outriggers;

(2) Connect water and electricity;

(3) According to the drilling plan, operate the remote control, move the boom to a suitable position, and perform drilling operations on the middle and upper steps; the operator operates the remote control to adjust the drilling status at any time to improve the drilling accuracy;

(4) After the middle and upper steps are drilled, move the machine to a suitable position to carry out the middle and lower steps drilling operations; completely solve the problem that traditional rock drilling rigs cannot be used to descend the steps;

(5) After the drilling operation is completed, use the remote control to operate the boom to the retracted state;

(6) Switch to chassis action, retract the outriggers, and move the machine to the parking space.

Construction Cases

The curved arm rock drilling rig installed in Wuxin Tunnel completely solves the problem of poor adaptability to step method construction, improves the adaptability of the rock drilling rig to different surrounding rock grades and different construction methods, and satisfies two-step, three-step, full-section, etc. All construction methods. Completely canceled the artificial bench construction method of weak surrounding rock, avoided the replacement of mechanical equipment due to the conversion of construction method, and improved the work efficiency and construction quality.Editor/Baohongying

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~