- Liebherr's new R 9600 meets the highest standards in the industry in terms of operational efficiency, reliability, durability and safety

After years of discussion and research and development, Liebherr brought the latest 600-ton R 9600 mining hydraulic excavator to the public.

Liebherr R 9600 is the replacement product of the popular "Internet celebrity" equipment R 996B. On the platform of Liebherr's 800-ton R 9800 excavator, it is continuously upgraded and optimized according to the actual needs of customers in daily work. , to create a new generation of products. The new R 9600 meets the highest standards in the industry in terms of operational efficiency, reliability, durability, safety, ease of service and cost per ton reduction.

Challenging zero emissions

The R 9600 is equipped with an engine power up to 2500 kW. Fuel cost is a major part of the total operating cost of mining equipment. If Liebherr uses LPE (Liebherr High Energy Efficiency) solutions, management systems dedicated to engine and hydraulic system control. Without compromising the overall productivity of the excavator, the R 9600 delivers nearly 40 percent better fuel economy than its predecessor.

If the mine has infrastructure such as grid power supply, the R 9600 can also be powered by a 6000V cable. For mines where diesel is expensive, this is an excellent choice, not only does not have to consider the daily maintenance, refueling and overhaul of the engine, but also can greatly reduce operating costs and achieve zero emissions.

Work equipment optimization

The R 9600 work equipment features optimized designs such as the patented "EVO" backhoe bucket, hydraulic cylinders, bucket linkages and work equipment pins. In this way, the excavator can increase the bucket capacity without affecting the life of each component, which greatly improves the overall production efficiency.

As a universal configuration, the R 9600 can be equipped with a backhoe bucket up to 37.5 cubic meters, with heavy duty wear parts, which perfectly matches Liebherr mining electric wheel trucks: four buckets can be filled with T 264 (240t) trucks, five buckets Can fill T 274 (300t) trucks and six buckets can fill T 284 (375t) trucks. In addition, the R 9600 excavator can be equipped with a 37-cubic bottom-dump shovel bucket.

Sturdy and durable

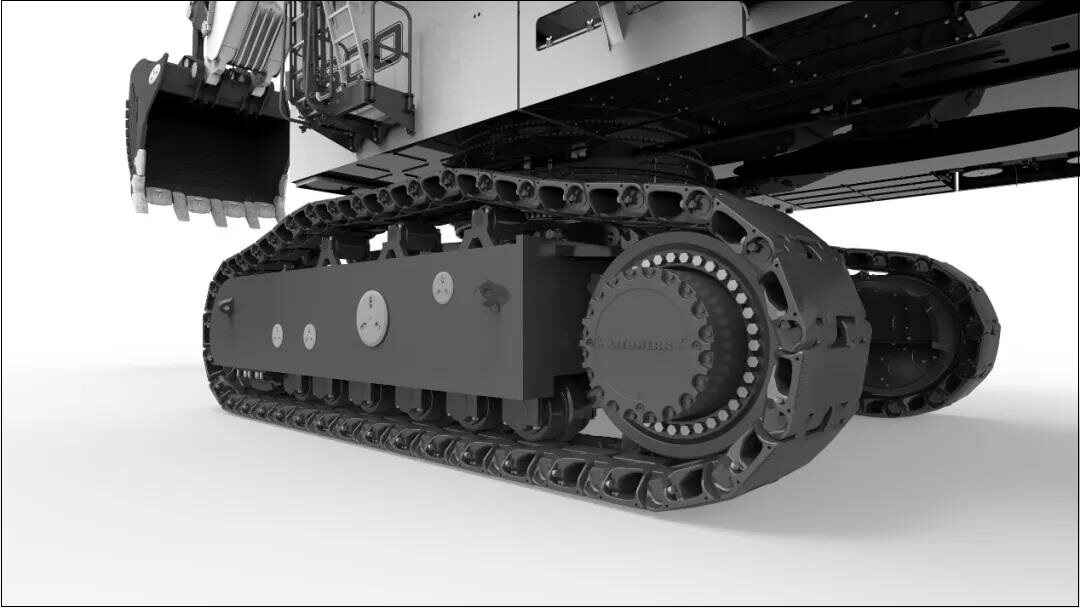

The R 9600 is designed to be widely used in all mines around the world, with ultra-long standby time and sustainable operation of more than 80,000 hours. In order to further improve the reliability of the equipment, the upper structure of the R 9600 has been completely redesigned. Robust chassis with fatigue-resistant steel construction and a new hydraulic track tensioning system. Standard equipment is fully sealed, maintenance-free for life, heavy-duty carrier rollers and track rollers, using Liebherr's patented raceway design and track shoe design.

The R 9600 is equipped with a state-of-the-art cab with a working space of nearly 14 cubic meters. The cab design reduces vibration and limits noise to 69 decibels, providing a comfortable working environment for the operator. In order to achieve the best working visibility, the cab of the R 9600 is placed on the left side of the machine, and the operator's seat is also arranged as far as possible from the center to the left, so that the operator can better see the work equipment and work area. . A complete lighting system makes night work easier and safer. The console is equipped with an advanced touch screen display. The air conditioning system adopts a modular design, and you can choose a single air conditioning system or a dual air conditioning system. The cab also offers a vacuum cleaner, premium cooling and ventilated seats, a filtration system and more. The R 9600 offers an excellent all-round visibility system for the equipment, including four cameras located at key positions on the vehicle. A dedicated monitor in the cab provides continuous 270° wide-angle monitoring around the equipment.

Work assistance systems and on-board control systems

The Liebherr R 9600 is equipped with the Liebherr Work Assist system. These advanced in-vehicle application systems, through the collection and analysis of real-time data, can provide operators with the best operation suggestions and help operators improve work efficiency. The matching mine dump truck loading assistance system can also help the operator to obtain the maximum production efficiency by optimizing the operation. With 99% accuracy, the system measures the instantaneous payload and provides real-time information to the operator. Truck Load Assist optimizes the number of loads to achieve the truck's target load.

In addition, the system can provide operators and customers with key performance indicators of equipment performance, assessments of job site conditions and equipment performance data in real time. In terms of the automation development of mining hydraulic excavators, Liebherr took the lead in introducing the bucket loading assistance system, which is an automatic or semi-automatic excavation system currently used in backhoe excavators. It maintains a consistent full load factor every dig, making it easier to fill the bucket, even in the toughest digging conditions. As a result, overall productivity is increased and operator fatigue is reduced.

Convenient service

Protecting customers' most important assets is a core philosophy at Liebherr. The R 9600 is designed to international standards for the safety of operators and service personnel, ensuring safety is always a top priority. The R 9600 has a hydraulically controlled, ergonomically placed 45° boarding ladder.

Safe and convenient inspection and maintenance are available from all parts of the equipment through walkways with handrails and non-slip steps. All major components are laid out for easy operation and easy maintenance. The hydraulically controlled lifting oil filling station can centrally fill various oils and greases, thereby reducing downtime.

Continue to write brilliant stories

Liebherr's new generation R 9600 is developed on the basis of the two ace excavators R 996B and R 9800 in Liebherr mining excavators. The R 996B is a highly acclaimed super large mining excavator that has been the star of the mining equipment market for the past 25 years.

In Australia in particular, more than 70% of excavators are still in normal operation, with a cumulative working time of 5.5 million hours. R 9600 is not only a replacement product of R 996B, but also draws on many advantages of 800-ton R 9800, which will surely create objective and significant benefits for new and old mine users in the future.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~