- Lovol FR420E2-HD excavator, equipped with Weichai WP10H engine and Linde hydraulic system, has strong power

China's commitment to double carbon to the world has also given more responsibilities to the construction machinery industry for energy conservation, emission reduction and green development, and it has also brought more challenges. According to statistics from the China Construction Machinery Industry Association, the 11 mainframe manufacturing companies included in the statistics will sell a total of 18,964 excavators of various types in October 2021, a year-on-year decrease of 30.6%. Under the influence of various factors, the situation of "involution" in the excavator industry has intensified, and the key to brand manufacturers to stand out is the creation of the core competitiveness of their products!

In the fiercely competitive market environment, traditional excavator equipment has been unable to meet the increasing demands of market users, and brand manufacturers have also begun to seek the transformation of traditional manufacturing and sales enterprises into intelligent working condition service providers and operators. Among them, the recent performance of domestic manufacturer Lovol is particularly dazzling.

Recently, the three new favorite excavators FR245E2/FR420E2-HD/FR600E2-HD launched by Lovol are jointly built by Weichai Power, Linde Hydraulics and Weichai Lovol Construction Machinery. Equipped with intelligent processing technology, it is a high-quality excavator tailored for domestic users. Once it was launched, it caused a warm response from market users!

first-class equipment

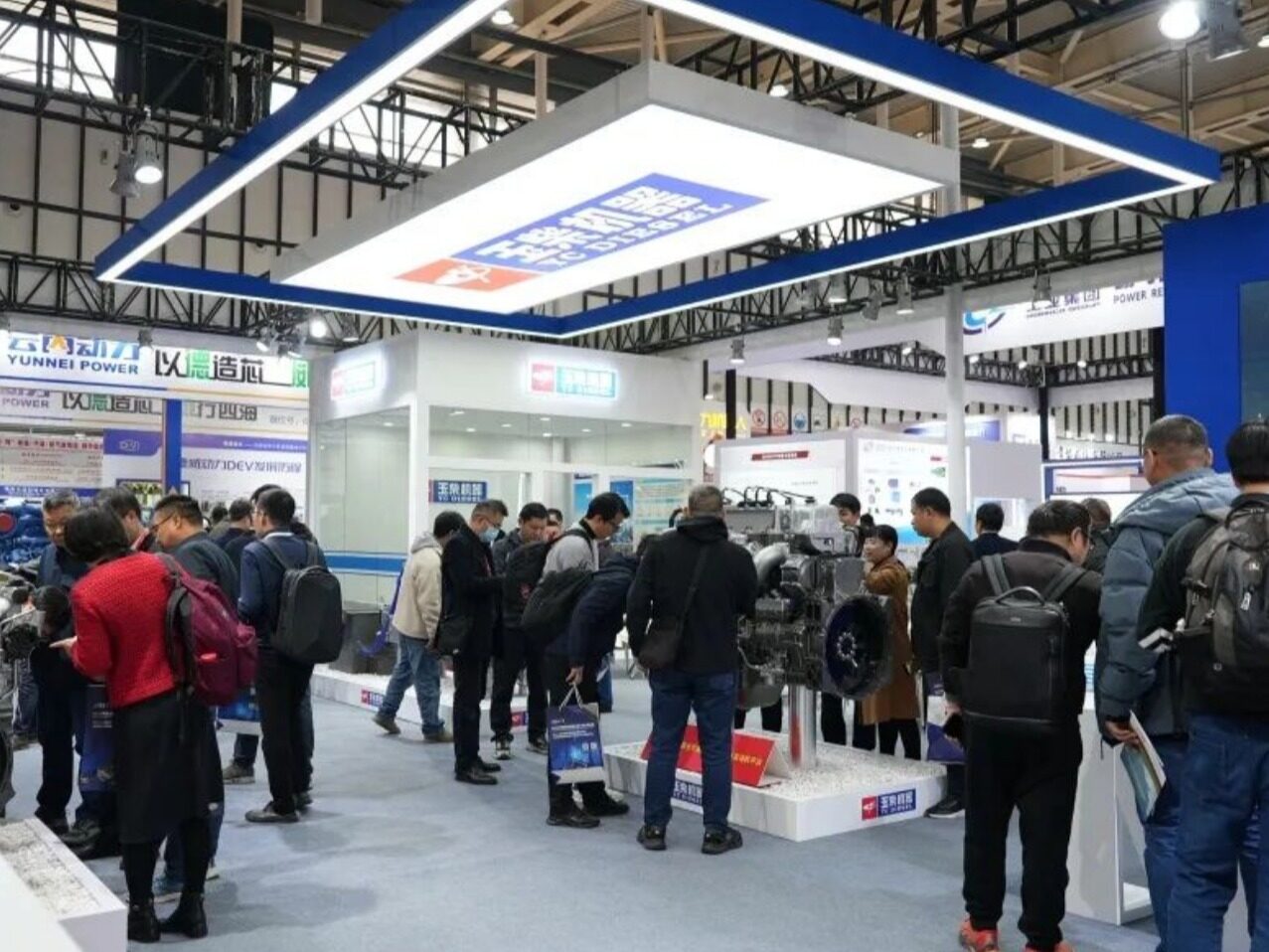

Over the years, Lovol's deep cultivation of electrification and intelligent core technologies has made many new excavator equipment obtain unprecedented improvement. In particular, the new Lovol FR245E2 excavator that participated in the 2021 Changsha exhibition performed very well.

The 22-ton Lovol FR245E2 crawler excavator is intelligent, reliable, safe and comfortable. It is an innovative work of Lovol Construction Machinery Group, Weichai Power and Linde Hydraulics. The FR245E2 excavator is equipped with a 155kw Weichai engine and Linde hydraulic powertrain, which can be flexibly and freely used in various working conditions such as earthwork excavation and loading in various infrastructure, municipal, and real estate.

The large displacement main pump has the characteristics of low noise and high efficiency and the main valve spool. FR245E2 adopts the customized main valve with high distribution efficiency, small pressure loss, and complex action coordination for synchronization, which makes the hydraulic system of the whole machine more controllable. Excellent and smooth. In addition, the FR245E2 adopts a high-torque rotary motor, which increases the dynamic torque by 11% and greatly improves the rotary sweeping capacity.

Among the later operating costs of excavators, higher work efficiency and lower fuel costs are valued by many users. However, accurate energy-saving control is achieved through the intelligent speed regulation of the Lovol FR245E2 excavator. The data shows that its fuel economy is improved by 15%, and the fuel consumption per hour is only 12L; the rotation start speed is faster, and the leveling operation is smoother; standard configuration 1.2 earth-moving bucket, the same ton bucket capacity is the largest, the fuel consumption is the lowest, and the efficiency is the highest. Mr. Li from Weifang, Shandong praised in an interview with Seedao.com, saying: "The first-class Lovol excavator equipment can't go wrong, it's not bad, and it saves costs."

The power core of noise reduction and energy saving

As a new star with full energy saving and noise reduction in mines, Lovol FR420E2-HD excavator does its part.

The 45-ton Lovol FR420E2-HD excavator is equipped with an 8-inch LCD touch screen display, which is easy to learn and use, and the operating status is clear at a glance. In terms of power, it is equipped with a brand-new Weichai WP10H engine and Linde hydraulic system. The hard-core double-king engine endows the FR420E2-HD excavator with surging power, precise and efficient capabilities. At present, the new series H platform loaded by Lovol excavators has completed the layout of the four non-road countries, and the performance of noise reduction and energy saving is very good.

It is reported that Weichai's new engine adopts the "low speed and large displacement" scheme, which reduces the engine speed and increases the displacement of the hydraulic pump to ensure the robustness and responsiveness of the engine, as well as the displacement of the cylinder and the speed of the hydraulic cylinder. Compared with similar products, the overall fuel efficiency of the whole machine has been significantly improved by more than 15%-17%. If the annual calculation is based on 2000 hours, the fuel cost alone will save about 20,000 to 90,000 yuan compared with competing products. The large fuel tank and excellent Combined with the high-torque rotary motor, it not only increases the dynamic torque by 13.5% compared with competing products, but also ensures the continuous high-intensity operation of the excavator and the rotary sweeping capacity is greatly improved.

The Lovol FR420E2-HD adopts a large-capacity oil pan: to meet the requirements of 35 inclination and 500 hours of oil change period, the structure is strengthened, and the noise is suppressed. It can realize the selection of various loading angles under different working modes such as buckets, breakers, hydraulic shears, steel grippers, and rippers on the same working platform, and improve the applicability of different loading conditions.

Weichai H platform structure and material technology are tailored for the characteristics of excavator working conditions, and the noise suppression technology is 2dB lower than that of similar diesel engines. Dean Leiwomeng said: "The quiet driving environment brings a comfortable working environment for users, and ultimately improves work efficiency and solves the noise problem that affects human life during the construction of large-scale equipment." And Mr. Gu from Hangzhou, Zhejiang said: "Lei Wo FR420E2-HD excavator has more power, larger bucket capacity, energy saving and better comfort.”

The ace assist of Linde hydraulics

As we all know, the matching of engine and hydraulic system is a key factor affecting the working efficiency and fuel economy of the whole machine. Lovol's 60-ton FR600E2-HD excavator uses the industry's top Linde hydraulic system as the ace aid.

Compared with the 249cc hydraulic system of the same ton level, the Linde main pump with the largest displacement is organically combined with the main valve spool optimized to reduce the load rate, which makes the hydraulic system control of the whole machine more precise and smooth. And the EGR made of super wear-resistant and super-corrosion-resistant materials realizes stable torque reserve output, strong power, excellent energy saving and flexible operation under different working conditions.

At the same time, the FR600E2-HD excavator is equipped with new technologies such as electronically controlled pedals, straight-through air filters and automatic lubrication, which greatly improves the operating feel; at the same time, the car is also equipped with one-button start, Bluetooth, and air suspension seat. It adopts humanized design such as chairs, and enlarges and widens the box structure of high-strength steel plate on the boom stick, which not only effectively relieves fatigue driving but also enables easy digging and loading of gravel in harsh and harsh working environments. Boss Zhang from a machinery company in Yunnan and Master Wang from a coal company in Inner Mongolia also applauded this, “It is impossible to go wrong with the Lovol excavator assisted by Linde Hydraulic Ace”, “It’s fast and good, and it saves costs.”

One-stop service, more convenient

The release of new Lovol excavators this time marks the achievement of Lovol Construction Machinery's practice of "adhering to customer-centricity", and along with the announcement of the new excavators, there is also the warranty of Weichai Linde powertrain products policy. According to the latest policy, the warranty period of the core components of the power hydraulic assembly of the equipment can reach 5 years or 10,000 hours, which is far ahead of the industry standard.

The hydraulic system of Lovol's new excavators has been fully upgraded, and the intelligence of the whole machine has been further improved. The after-sales service network system covering the whole country is even more powerful! Dean Meng of Lovol further emphasized: "The service and maintenance network of power hydraulic assembly is all over the country, and the timeliness of service response is reliably guaranteed." convenient!"Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~