- Up to now, China Railway has equipped tunnel boring machines (shield machine/TBM) all over the country and exported to overseas

On May 10, 2014, General Secretary Xi Jinping inspected China Railway Equipment, a subsidiary of China Railway Industry, and made important instructions to "promote the transformation of Chinese manufacturing to Chinese creation, Chinese speed to Chinese quality, and Chinese products to Chinese brands".

Practicing the "Three Transformations" Important Instructions

Be the first brand of tunnel boring machines in China

The important instructions of the "Three Transformations" point out the direction for the high-quality development of Chinese manufacturing. In 2017, the State Council approved the establishment of May 10 each year as "China Brand Day".

In July 2021, General Secretary Xi Jinping inspected the "Snowy Pioneer" model of the first domestically produced plateau alpine large-diameter hard rock roadheader developed by China Railway Equipment during his inspection tour in Tibet. The "Xueyu Pioneer" (10.33 meters in diameter) is used in the construction of the road network on the Qinghai-Tibet Plateau. It is the largest diameter open road roadheader made in China and the world's first dual-structure hard rock roadheader.

Innovation drives development

Honor highlights the brand

Innovation is the inexhaustible driving force for enterprise development.

As the "Birthplace of China Brand Day" and the source of original technology for the manufacture of heavy equipment in a major country, China Railway Equipment has kept in mind General Secretary Xi Jinping's entrustment and guided by the important instructions of "Three Transformations" to continue to strengthen key core technologies of tunnel boring machines. Gao Feng, with the super-qualification for the production of roadheaders, has created a large number of tunnel roadheader products with the most advanced technology, the largest number, the most arduous tasks and the best performance in China, and has won a series of honors and commendations both inside and outside the industry.

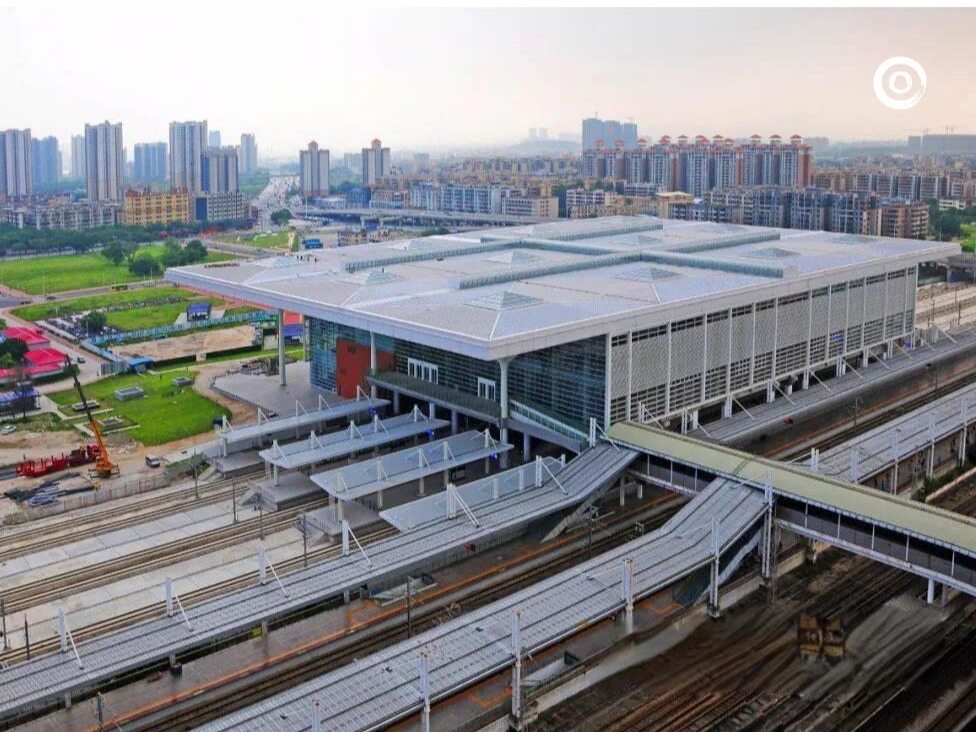

Up to now, the production and sales volume of China Railway Equipment’s tunnel boring machine (shield machine/TBM) has been ranked first in the world for five consecutive years and in China for ten consecutive years. , UAE, Denmark, Austria, Poland and other 30 countries and regions.

In the field of large shield machines with a diameter of more than 10 meters, China Railway Equipment has maintained a number of "domestic and international firsts": developed the world's largest diameter (15.08 meters) full-section hard rock boring machine (TBM) "Caucasus"; designed and manufactured 10 There are nearly 50 large-diameter shield machines above meters and nearly 30 large-diameter shield machines above 13 meters, ranking first in China; 13 large-diameter shield machines have been exported overseas, ranking first in China; the excavation mileage of large-scale shield machines has exceeded 50 kilometers. It ranks first in China's tunnel boring machine industry.

On September 29, 2020, the 1,000th shield machine independently developed by China Railway Equipment rolled off the assembly line. China Railway Equipment has become the first leading enterprise in China to exceed 1,000 tunnel boring machines.

"From 0 to 1, from 1 to 1000, the 1000th shield machine independently developed by China Railway Equipment has been offline, indicating that my country's shield technology is moving from quantitative accumulation to qualitative leap, from point breakthrough to system capability improvement. " said Yang Huayong, an academician of the Chinese Academy of Engineering.

The world's largest TBM

Top Students in Tunnel Boring Machines

In the Georgian Caucasus Mountains at an altitude of 2,000 meters, the world's largest diameter (15.08 meters) full-section hard rock boring machine (TBM) "Caucasus" developed by China Railway Equipment is driving.

In view of the construction problems caused by the long distance and large burial depth of the project, China Railway Equipment adopts the active articulation system, the bidirectional rotary cutter head, the two-speed reducer system, and the synchronous assembly of the box and culvert. Equipped with large buried depth equipment and strong escape ability, so that the equipment has efficient tunneling ability under different geological conditions.

Up to now, the "Caucasus" has excavated more than 1,200 meters, creating a good result of 16 meters of footage per day.

The smartest big shield

Solve world-class puzzles

Dalian Metro Line 5, the submarine tunnel from the railway station to Barracuda Bay South Station has high-strength hard rock formations, long excavation distances, high safety risks, large burial depths, and high water pressure. The karst that has to pass through more than 1,000 karst caves is strongly developed The area has been characterized by industry experts as an unprecedented "worldwide problem".

For this project, the "Haihong" shield machine with a diameter of 12.26 meters developed by China Railway Equipment integrates a variety of international leading technologies and successfully solved a number of world-class problems. It is called "the smartest shield machine".

On January 11, 2021, the "Haihong" was successfully completed, accumulating valuable experience for the long-distance hard rock large shield construction in the submarine karst formation in the "crossing the river and the sea" tunnel in the world.

Heavyweight of the country

Challenge the "Geological Museum"

The Gaoligongshan Tunnel of the Darui Railway is 34.5 kilometers long. It is the first long railway tunnel in China. The maximum burial depth of the tunnel is 1155 meters. It has the characteristics of high geothermal heat, high geostress and high seismic intensity. ".

China Railway Equipment tailored the world's most advanced large-diameter open tunnel hard rock boring machine "Caiyun" for the Gaoligongshan Tunnel.

The equipment was rolled out on August 1, 2017, and the excavation diameter of the cutter head reached 9.03 meters, filling the gap of domestic hard rock roadheaders with a diameter of more than 9 meters. Into the Ministry of Transportation" campaign.

Fill multiple technical gaps

Be among the world's leading

Unlike North China, where there are many alluvial plains, thick soil layers, and less difficulty in tunnel construction, South China is mountainous. Granite is the most common bedrock rock of various landforms, and there are also many sandstone and metamorphic rocks. The geology is very complex and the rock hardness However, the number of large shields equipped by China Railway Group accounts for more than 60% of the large shields used in South China.

Among them, the most representative is the "Spring Breeze" shield machine (15.8 meters in diameter). The equipment is used in Shenzhen Chunfeng Tunnel Project. The excavation section passes through 11 crushing zones, and 3.6 kilometers of rock layers are excavated at a time. It is one of the most challenging large-diameter shield machine projects in the construction of shield method promotion and is rated as a central enterprise. Ten innovative projects.

The world's first special-shaped shield

Won the industry's highest honor

The world's first horseshoe-shaped shield "Menghua" independently developed by China Railway Equipment was successfully applied to the Baicheng Tunnel of the Haoji Railway. "The earth pressure balance shield method using large-section horseshoe shape was applied to loess tunnel for the first time" won the "International Tunnel Association 2018 Technology Innovation Project Award". The award is the highest award in the international tunnel industry and is known as the "Oscar" of the tunnel industry.

Continuing the spirit of the Red Boat

Climb the world's peak

China Railway Equipment Co., Ltd. has continued to be the pioneer and indomitable "Red Boat Spirit", concentrated its technical strength, strengthened scientific research, overcome many difficulties, and developed the world's largest rectangular shield machine - "Nanhu" (width 14.82 meters, height 9.446 meters) ) for the municipal project in Jiaxing, Zhejiang, the birthplace of the "Red Boat Spirit". "Nanhu" solved the technical problems of one-time excavation and formation, host attitude control and soil settlement control in the construction of super large cross-section rectangular shield machine, and created a precedent for the use of rectangular shield machine in the construction of 3-lane rectangular tunnels.

Small shield with great power

Serve the people's livelihood

The domestic smallest diameter mud-water balance shield machine "Hanfeng" (China Railway No. 1084) developed by China Railway Equipment was applied to the quality and efficiency improvement project of the sewage pipe network in Quanshan District, Xuzhou City, Jiangsu Province, to overcome the split start in a narrow space and the minimum turning radius Many challenges, such as the 100-meter curve section excavation, the limited space operation of the extremely small section, and the shallow overburden construction of the mud-water shield, have created a good performance.

Continuously develop larger, smaller and more advanced shield machines, and constantly refresh new heights in the field of tunnel boring machines in the world. China Railway Equipment continues to write a new chapter in the industry to serve the country with innovation and progress, and be the first brand of China's tunnel boring machines. , leading the new direction of world shield development. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~