- Since the Luanhe Bridge on the Beijing-Zhangjiakou Railway a hundred years ago, CREC has been closely linked with steel bridges

On April 19, 2022, the International Institute of Welding (IIW) issued a notice that the Hong Kong-Zhuhai-Macao Bridge, which was built by CREC's China Railway Shanqiao, China Railway Baoqiao and other units, won the "Ugo Guerrera Prize" of the International Institute of Welding.

The "Ugo Guerrera Prize" is the highest award in international welding, awarded to large-scale outstanding welding engineering technical teams in the field of international engineering construction in the past ten years. It is selected every three years. The Hong Kong-Zhuhai-Macao Bridge project was recommended and selected by the China Welding Society. After the "Bird's Nest" project of the National Stadium, the main venue of the Beijing Olympic Games in 2010, China has won the highest international welding award again.

At present, CREC and its affiliated companies have accumulated six super-qualified Chinese steel structure manufacturing enterprises, and the steel structure projects that participated in the construction of the Guanting Reservoir Highway Bridge, Qinghai Haihuang Bridge, Hong Kong-Zhuhai-Macao Bridge and other steel structure projects have successively won the highest quality honors for engineering construction and welding in China. The first prize and the special prize for excellent welding engineering fully reflect CREC's strong technical strength and strong industry voice in the field of steel structure manufacturing.

The Hong Kong-Zhuhai-Macao Bridge is another major infrastructure construction project in China after the Three Gorges Project and the Qinghai-Tibet Railway. This is the longest sea-crossing bridge in the world so far, and is known as the "crown" in the history of bridge construction in the world. The designed service life is 120 years, meeting the requirements of safety, environmental protection, durability, comfort and beauty.

In the process of participating in the construction, CREC's China Railway Shanqiao and China Railway Baoqiao undertook the production and manufacturing tasks of more than 223,000 tons of steel structures; China Railway Mountain Bridge, China Railway Science and Industry, and China Railway Nine Bridges also developed special hoisting, transportation, etc. for the bridge. equipment.

In the manufacture of the steel box girder of the Hong Kong-Zhuhai-Macao Bridge, CREC took the lead in carrying out the research on the automatic manufacturing and welding technology of the panel unit, and formed a set of panel unit manufacturing expertise with automation, informatization and intelligence as the main means, and solved the problem of U-shaped panel unit manufacturing. The problem of poor welding quality and stability of rib fillet welds breaks the traditional steel bridge manufacturing mode, improves the level of automated welding, and realizes the production requirements of "large-scale, factory-based, standardized, and assembled"; the first application of robotic welding technology to In the field of domestic steel bridge manufacturing, the first automatic production line of plate units in China was built; for the first time, the coating-free weathering steel welding technology was used in the manufacturing of large-span steel bridges in China, which ensured the manufacturing quality and construction period of the Hong Kong-Zhuhai-Macao Bridge, and provided the technical support for China's steel bridge manufacturing industry. And equipment upgrades play a leading and exemplary role.

Relying on the manufacturing of the Hong Kong-Zhuhai-Macao Bridge, a series of welding technology research has been carried out, and a modern intelligent welding production workshop for orthotropic plate units has been built. It has obtained 7 invention patents and 3 utility model patents, leading the development of China's steel bridge manufacturing technology. .

A bridge flying through the sky, iron shoulders shoulder the dream of a strong country.

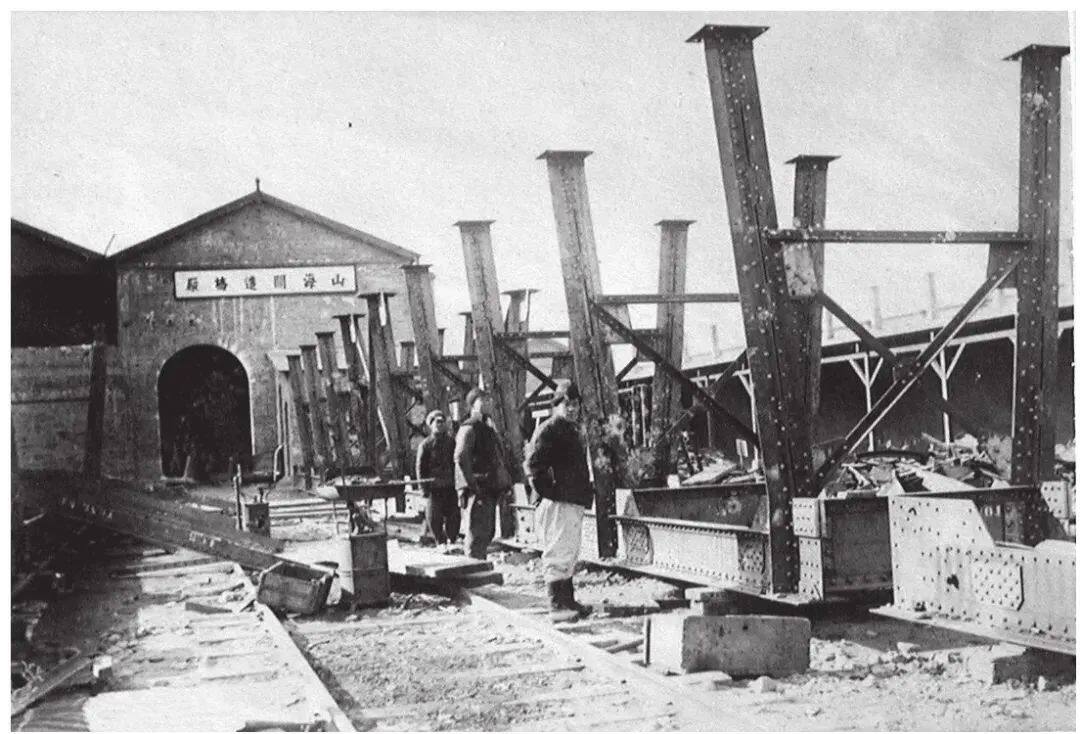

On April 11, 1894, in the impoverished and weak Qing Dynasty, China's first large-scale steel bridge, the Beijing-Fengshan Railway Luanhe Bridge, was completed, creating a history of China's self-built steel structure bridges. With 300 bridging technicians as the team, Beiyangguan Railway Bureau Shanhaiguan Bridge Factory (the predecessor of China Railway Shanqiao) was born and became the historical origin of CREC.

Shanhaiguan Bridge Factory

The times are the testers, we are the respondents, and the people are the testers.

Over the years, CREC's affiliated units such as China Railway Shanqiao, China Railway Baoqiao, China Railway Science and Industry, China Railway Equipment, etc., have kept in mind General Secretary Xi Jinping's entrustment, practiced the "three transformations", adhered to the "big country" in mind, actively participated in the national strategy, and fully Give full play to its own advantages, help the construction of major national projects, and continue to write a new chapter of industry serving the country.

Nanjing Yangtze River Bridge

Beginning with the Luanhe Bridge on the Beijing-Zhangjiakou Railway a hundred years ago, CREC has been closely linked with steel bridges, creating and witnessing the development history of China's steel bridges. Time and again, technological revolutions have driven China from a big bridge-building country to a bridge-building power.

At present, CREC has manufactured more than 5,000 steel bridges. CREC's subsidiaries, including China Railway Shanqiao, China Railway Baoqiao, China Railway Science and Industry, China Railway Nine Bridge, China Railway Heavy Industry and other units, have successively participated in the construction of Wuhan Yangtze River Bridge, Nanjing Yangtze River Bridge, Bangladesh Padma Bridge, etc. A large number of super-long and super-large bridges represented by bridges, etc., have a domestic market share of over 60%; among the top 100 bridges in the world, the share of ; A number of steel bridge intelligent manufacturing factories lead the world's steel bridge intelligent manufacturing, and the products have been successfully exported to developed countries such as Europe and the United States; the only steel tower machining center in China has been built, and the machining accuracy of bolted steel tower end faces is world-class.

The company produces more than 1.2 million tons of steel bridges and steel structure products annually, creating a precedent for the factory-based, automated, and information-based manufacturing of large-scale steel bridges in China. The manufacturing automation and factory-based technologies for large-span heavy-duty bridge steel structures have reached the world level. Leading level is the promoter of China's successful transition from a "bridge power" to a "bridge power".

CREC's construction of a domestically leading, world-class, and exemplary steel bridge intelligent manufacturing demonstration factory is an important measure for CREC to implement the "three transformations", actively respond to the national intelligent manufacturing development requirements, and implement the strategy of deep integration of industrialization and informatization.

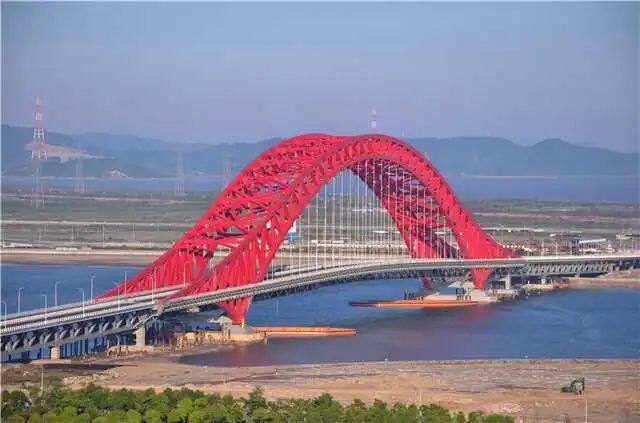

Currently, the second Wuhu Yangtze River Bridge, Wuhan Tianxingzhou Yangtze River Bridge, Nanjing Dashengguan Yangtze River Bridge, Qingdao Bay Bridge, Maanshan Yangtze River Bridge, Zhangjiajie Grand Canyon Glass Bridge, New Shougang Bridge, Hong Kong-Zhuhai-Macao Bridge, Yang Si The Hong Kong Yangtze River Bridge and others have successively won the IBC Bridge Project Award, making the "China Steel Bridge" brand shine in the international bridge session.

In the Verrazano Narrows Bridge project in the United States, officials from the New York Metropolitan Transportation Authority fully affirmed: "Chinese companies are already 'experts' in the field of manufacturing bridge components."

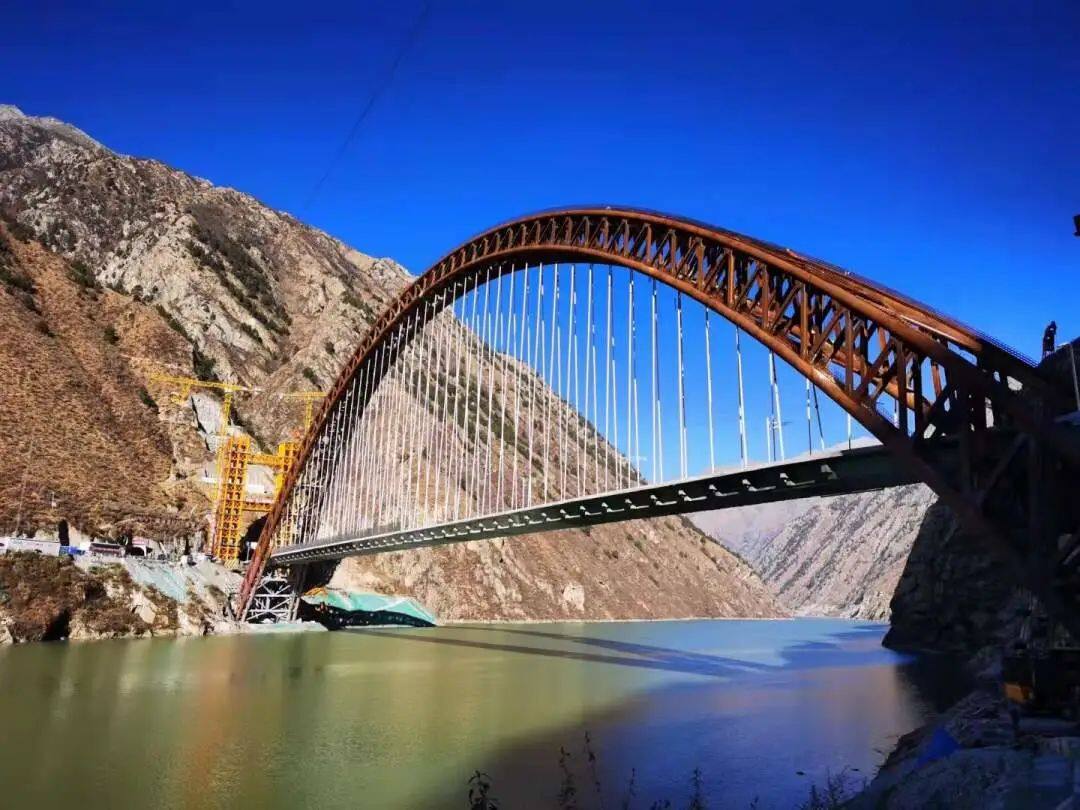

Zangmu Yarlung Zangbo River Bridge

The Lalin Railway Zangmu Yarlung Zangbo River Bridge won the Railway Bridge Award. It is the CFST arch bridge with the largest railway span in the world and the CFST arch bridge with the highest altitude and seismic intensity. The Zangmu Bridge is made of high-strength weathering steel, and the whole bridge is free of coating. It is the first real coating-free weathering steel bridge in China. The bridge was awarded the Theodore Cooper (Railway Bridge) Award by the International Bridge Congress (IBC) 2022.

Shanghai-Sutong Yangtze River Bridge

The Shanghai-Sutong Yangtze River Bridge has solved the welding problem of Q500qE high-performance bridge steel, and as a key technology, it supports the welding construction of world-class bridge projects such as the "Hu-Su-Tong Bridge Yangtze River Bridge", the world's first road-rail dual-purpose cable-stayed bridge with a span of over 1,000 meters. , a number of technical indicators have reached the highest international level, and it was listed as a national key research and development project in 2017. The bridge won the "George Richardson Award".

Meishan Chunxiao Bridge

The Meishan Chunxiao Bridge built by CREC won the 2020-2021 China Construction Engineering Luban Award (National Quality Project) and the 2020-2021 Li Chun Award (Highway Traffic Quality Engineering Award). The association awarded the honorary title of "Excellent Project Builder".

Pingtang Bridge

The Guizhou Pingtang Bridge, which CREC participated in, won the highest award of the 38th International Bridge Conference (IBC) - the Gustav Linden Award.

Cuntan Yangtze River Bridge

The Chongqing Cuntan Yangtze River Bridge, which CREC participated in, won the 2020-2021 National Quality Project Award.

New Baishatuo Yangtze River Bridge

The new Baishatuo Yangtze River Bridge that CREC participated in won the 18th China Civil Engineering Zhan Tianyou Award.

Guantang Bridge

The steel box arch of Guangxi Liuzhou Guantang Bridge, which CREC participated in, won the first prize of the 2021 Excellent Welding Project.

Changtai Yangtze River Bridge

The main channel bridge of Changtai Yangtze River Bridge in Jiangsu adopts a double-deck 1176-meter cable-stayed bridge, and the special channel bridge has a main span of 388 meters steel arch bridge, both of which have set new world records for similar bridges.

Padma Bridge, Bangladesh

The Padma Bridge is currently the largest bridge-building project in Bangladesh. It is the first steel truss bridge with all-welded structure, super-thick plate, and both road and rail that adopts European standards. Amount of monomer bridge project.

Slussen Bridge, Sweden

CREC China Tieshan Bridge is the only Chinese manufacturer for the Slussen Bridge project. "CREC "Sweden 'Golden Bridge' Polishing Brand Made in China" Case" was successfully selected into the "2021 International Image Construction of Chinese Enterprises - International Communication Cases" sponsored by the State-owned Assets Supervision and Administration Commission of the State Council and the Foreign Languages Administration.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~