- The project can reduce carbon dioxide emissions by 1 million tons per year

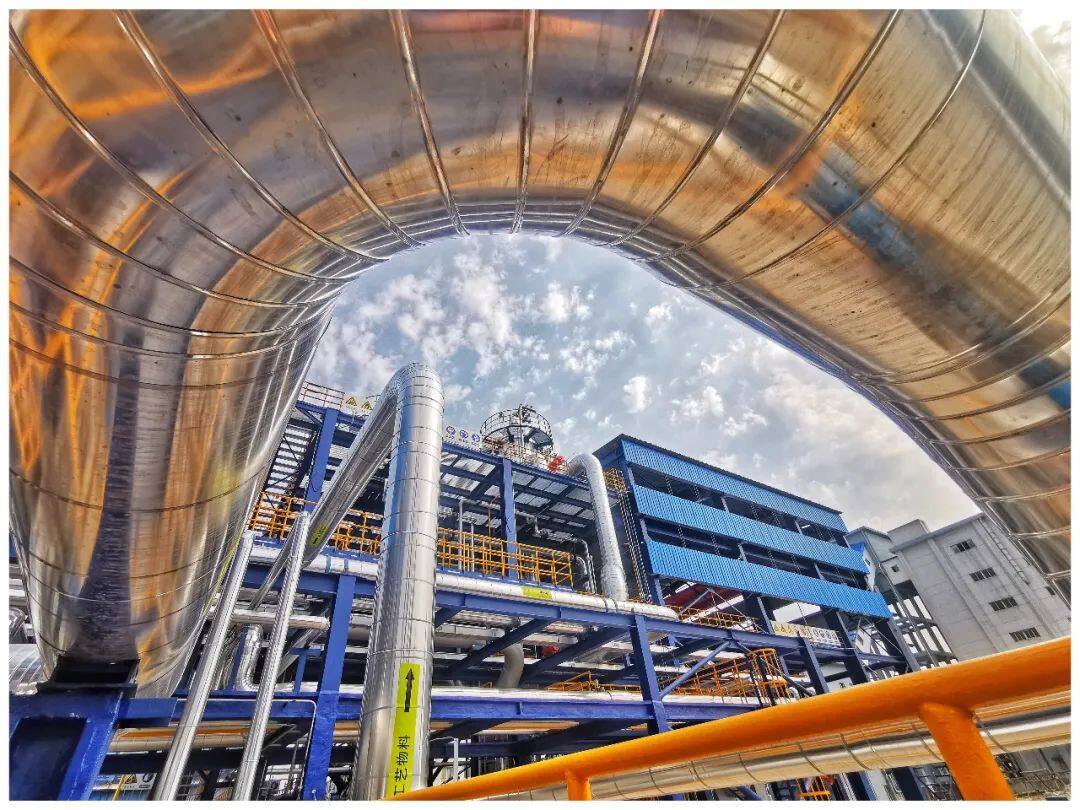

On August 29, 2022, Sinopec announced that China's largest carbon capture, utilization and storage full-industry chain demonstration base and the first domestic megaton CCUS project Qilu Petrochemical - Shengli Oilfield megaton CCUS project officially started gas injection. It marks that China's CCUS industry has begun to enter the middle and late stage of technology demonstration and mature commercial operation.

CCUS can achieve a win-win situation of oil production increase and carbon emission reduction, and is an emerging technology for low-carbon and efficient development of fossil energy. Carbon capture, utilization and storage is referred to as CCUS, that is, the carbon dioxide emitted in the production process is captured and purified, and then put into a new production process for reuse and storage. Qilu Petrochemical - Shengli Oilfield million-ton CCUS project captures and provides carbon dioxide from Qilu Petrochemical, and transports it to Shengli Oilfield for oil displacement and storage, realizing the integrated application of carbon dioxide capture, oil displacement and storage. The project covers more than 25 million tons of ultra-low permeability oil reserves, and a total of 73 injection wells are deployed. It is estimated that the cumulative injection of more than 10 million tons in 15 years will increase oil by nearly 3 million tons, and the recovery factor will increase by more than 12 percentage points.

China has huge potential for geological storage of carbon dioxide, and has engineering capabilities for large-scale capture, utilization and storage. Practice has proved that the development of CCUS can greatly improve the development and utilization rate of low-grade resources, and provide support for ensuring national energy security. As a carbon reduction and carbon sequestration technology, CCUS has become an important part of the carbon neutrality action plans of many countries. Although China's CCUS is in the demonstration stage of industrialization, which is comparable to the overall international development level, some key technologies are still far behind the international advanced level. Over the years, Sinopec has continued to carry out scientific research to promote the development of my country's CCUS industry.

Carbon capture link, realize the localization of all equipment

The carbon source of Qilu Petrochemical comes from the coal gasification unit of the company's second fertilizer plant. The carbon dioxide tail gas emitted by this unit is a high-quality carbon dioxide resource, with large emissions and stable performance, with a purity of up to 90%. Qilu Petrochemical uses liquefaction and purification technology to recover carbon dioxide from the tail gas of coal gasification units, which is more energy-saving and lower in cost, and all devices at the carbon capture end are localized. At the same time, the CCUS project adopts a number of green technologies to reduce the energy consumption of the device and reduce carbon emissions. Sinopec has a number of core technologies in carbon utilization and storage.

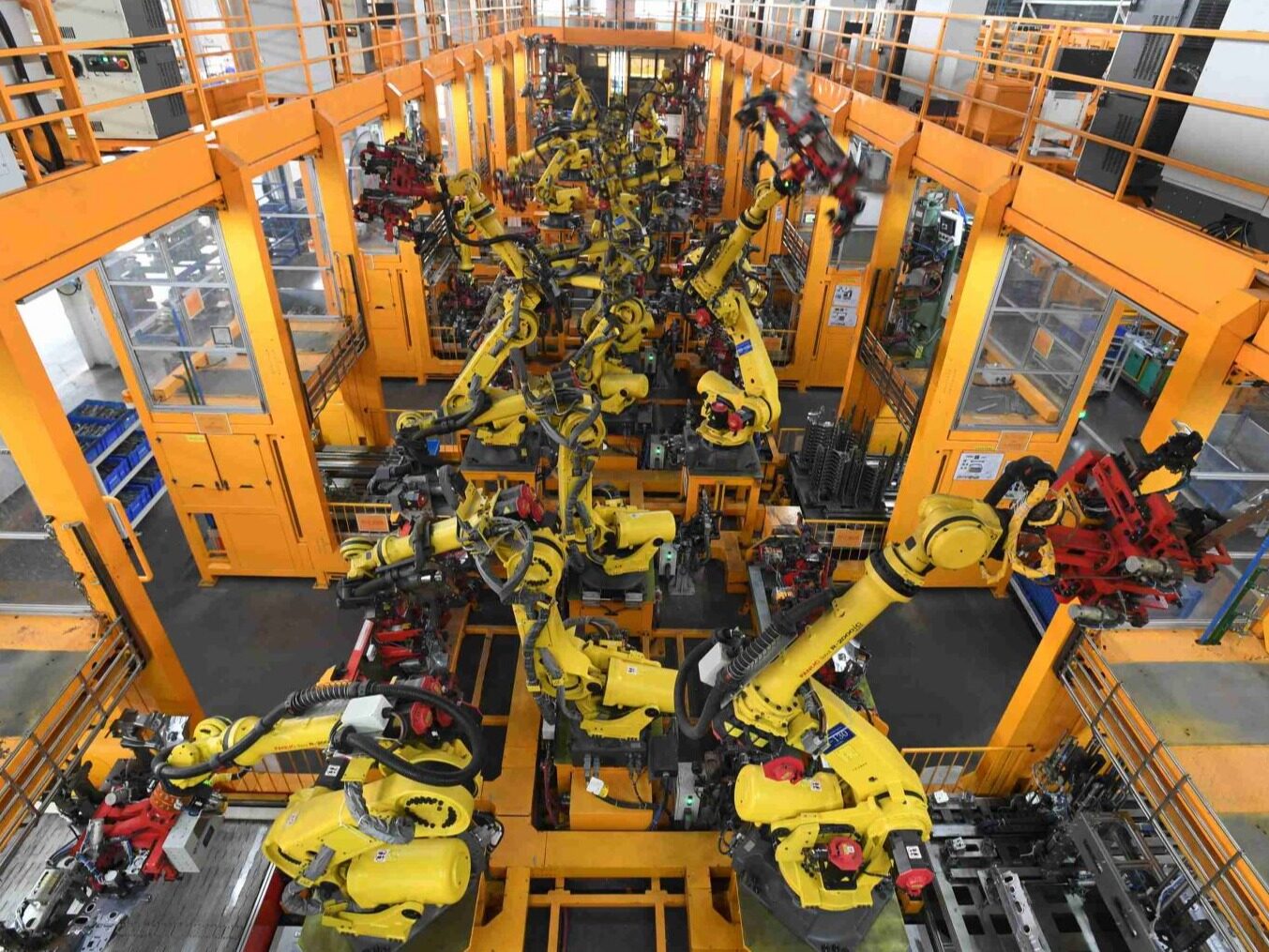

To improve the storage rate and recovery rate of the CCUS project, the whole process of sealing is the core. At the injection end, in view of the difficulty of liquid carbon dioxide gasification and efflux and the difficulty of multi-well simultaneous injection, measurement and distribution, Shengli Oilfield has developed a fully enclosed and efficient injection technology, and has formed a series of injection equipment with completely independent intellectual property rights, which has solved the problem of zero emission. core technical problems such as low temperature metering, partial pressure and separate injection; at the production end, innovatively implement the whole process of closed collection, transportation and treatment of the produced gas and liquid, and the produced gas and water are transported to the reinjection station and directly pressurized and reinjected into the formation for secondary Secondary oil displacement and storage ensure that oil does not fall to the ground, water is not discharged, and gas does not go to the sky. Shengli Oilfield has formed the core technology of carbon dioxide high-pressure miscible flooding and achieved breakthroughs in mine application. A total of 640,000 tons of carbon dioxide has been injected into 20 blocks, more than 500,000 tons of carbon dioxide have been stored, and more than 100,000 tons of oil have been added.

In the transportation link, the first long-distance supercritical pressure pipeline transportation of carbon dioxide in China is about to be realized. At present, the carbon dioxide captured by Qilu Petrochemical is transported by land vehicles and sent to Shengli Oilfield for oil displacement and storage. According to the plan of Sinopec, it is expected that by the end of this year, the 100-kilometer carbon dioxide transmission pipeline from Qilu Petrochemical to Shengli Oilfield will be put into operation. At that time, the long-distance supercritical pressure pipeline transportation of carbon dioxide will be realized for the first time in China. Fully enclosed.

In 2021, Sinopec's carbon dioxide capture volume has reached 1.52 million tons, and the application of CCUS has achieved good results. In 2012, the first CCUS project of a domestic coal-fired power plant was launched in Shengli Oilfield, forming a comprehensive technology and economic evaluation technology for the integrated project of carbon dioxide capture, oil displacement and storage from the flue gas of coal-fired power plants. In 2015, Southern Chemical Company and East China Petroleum Bureau cooperated, and the liquid carbon company of East China Petroleum Bureau adopted the production and sales contract mode to recover the carbon dioxide tail gas from the synthetic ammonia and coal-to-hydrogen units of the Southern Chemical Company, and used it for oil field pressure injection flooding, which opened Sinopec's internal It is a precedent for the comprehensive utilization of carbon dioxide resources between upstream and downstream enterprises. In 2021, Sinopec will capture about 1.52 million tons of carbon dioxide, which has achieved good results in improving crude oil recovery and reducing carbon emissions. During the 14th Five-Year Plan period, Sinopec will intensify construction efforts to realize the industrialized development of CCUS.

So far, Sinopec has implemented 36 carbon dioxide flooding projects, laying a solid foundation for the rapid development and large-scale application of CCUS technology. During the 14th Five-Year Plan period, Sinopec will study and establish a carbon capture, utilization and storage technology research and development center, focus on the deployment of CCUS+ wind power, CCUS+ hydrogen energy, CCUS+ biomass energy and other cutting-edge and reserve technologies, and increase the production of high-value chemicals from carbon dioxide. , carbon dioxide mineralization and utilization and other technical application efforts, break through the core technology and key equipment problems in carbon capture, transportation, utilization, storage and other links, build a technology development-engineering demonstration-industrialized carbon dioxide utilization technology innovation system, and extend clean carbon sequestration Industrial chain, and create a source of carbon emission reduction technology innovation. Keywords: engineering news, construction news

During the 14th Five-Year Plan period, Sinopec will rely on the carbon dioxide generated by Shengli Power Plant, Nanhua Company and other enterprises, and strive to build two more million-ton CCUS demonstration bases in its subsidiary Shengli Oilfield, East China Oil and Gas Field, and Jiangsu Oilfield to realize CCUS industrialization. Development will open up broader prospects for my country to achieve the goal of carbon peaking and carbon neutrality.Editor/XingWentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~