- The entire integrated base is planned to be completed in 2030, and the first production unit will be put into operation in 2022

- This project is BASF's largest investment project so far and has become BASF's third largest integrated production base in the world, after Ludwigshafen, Germany and Antwerp, Belgium.

BASF, the world's largest chemical complex, once reap huge benefits from high-quality and low-cost Gazprom. According to the data, 60% of the natural gas consumed by BASF is used for power generation and steam, and 40% is used as raw material for products. Because natural gas is needed everywhere, these enterprises are extremely vulnerable to the "gas shortage". When natural gas falls below a certain level, entire chemical plants will have to shut down.

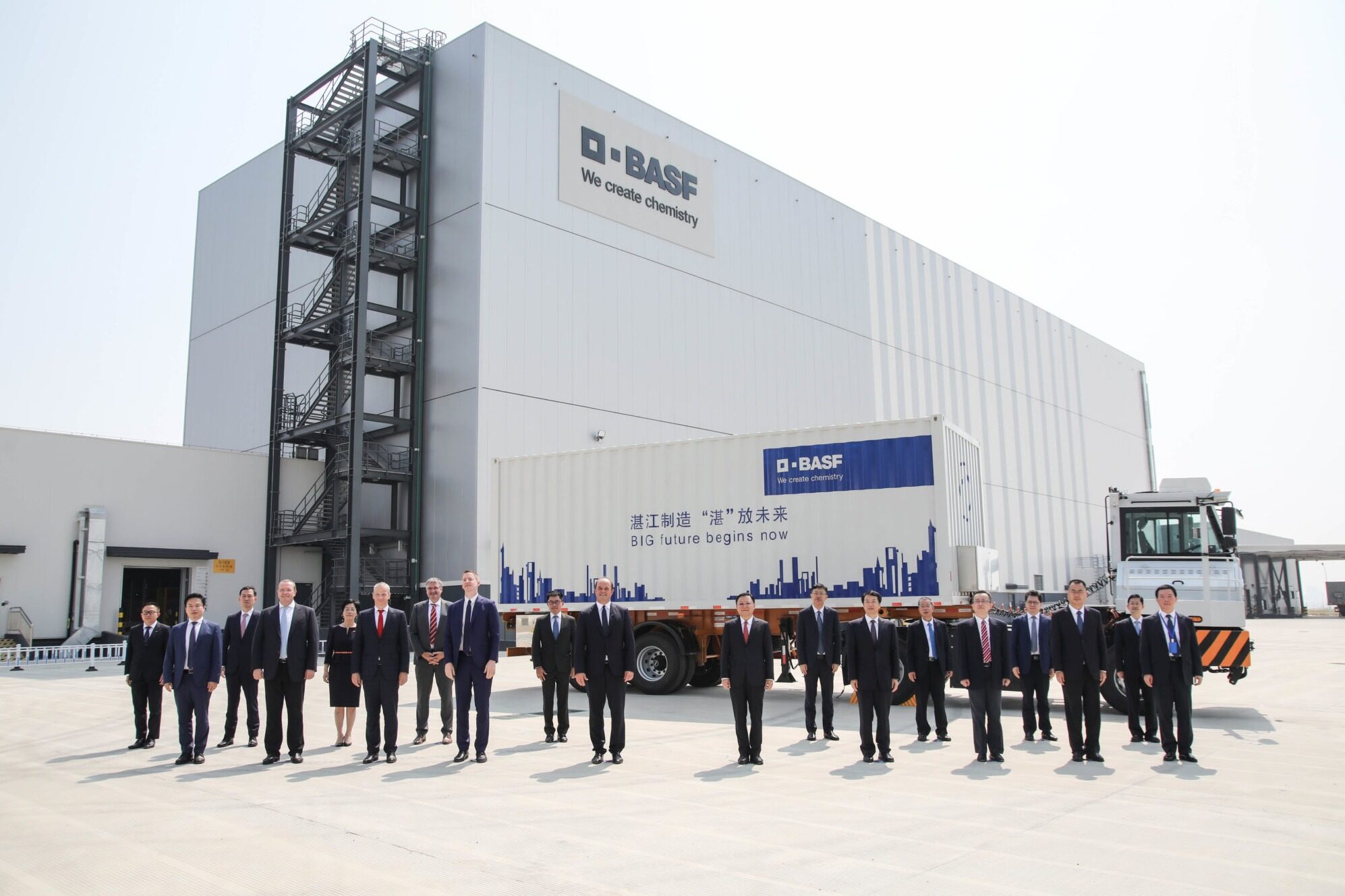

At present, BASF is looking to China for "help"! BASF is preparing to "transfer flowers to join trees" and invest 10 billion US dollars to build a production base in Zhanjiang, China. Because China's chemical market is the largest and fastest growing in the world. This will be BASF's largest investment project!

German chemical company BASF has begun construction of a petrochemical plant worth 10 billion euros in China's Guangdong province. BASF said that this is the largest investment ever made by a German company in China. The integrated factory complex in the city of Zhanjiang will be completed in 2025, making it the third largest of BASF's 390 production sites worldwide. It will run entirely on renewable energy.

BASF started construction of an initial production unit in 2020, which is now operational. The plant will supply 60,000 tons of engineering plastic compounds per year, especially for the automotive and electronics industries. This will bring BASF's total production capacity in the Asia-Pacific region to 420,000 tons.Editor/XingWentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~