- This drilling rig is China's first 8000-meter silent automatic drilling rig developed by BOMCO for COSL.

- In the kingfisher oilfield, the BOMCO after-sales service team completed the lifting of the rig in just over 40 days

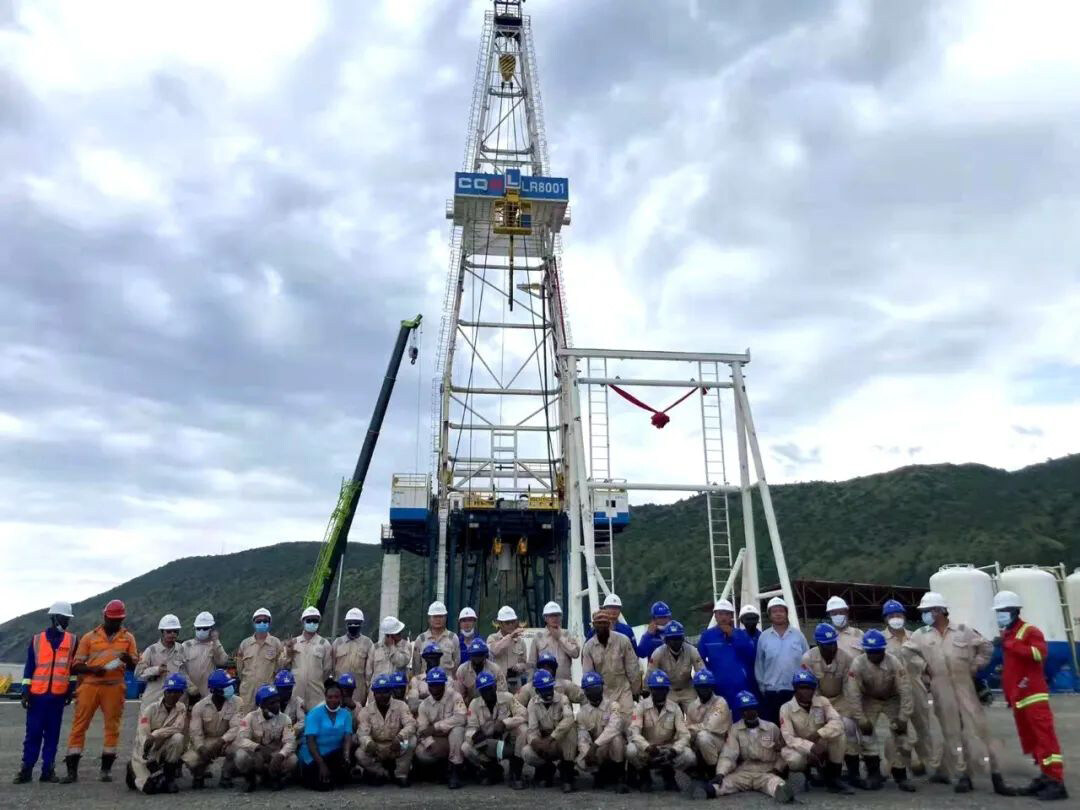

On November 6, 2022, local time in Uganda, COSL's 8,000-meter silent automatic drilling rig "LR8001" was successfully lifted in Kingfisher Oilfield in Uganda.

The drilling rig is China's first 8,000-meter silent automatic drilling rig developed by BOMCO for COSL. After the drilling rig was shipped, in order to ensure the smooth operation of users abroad, a service team composed of 14 employees from the Offshore Oil Equipment Branch, the National Research Center, the Drilling Rig Branch, the Automation Equipment Branch, and the supporting manufacturers successively stationed in the oilfield well team and actively developed the drilling rig. After-sales service work.

The actual situation in Uganda has brought great challenges to the service work. In the face of the complex working environment, the company's after-sales service team is united and shoulders heavy responsibilities, strictly abides by the safety production regulations of COSL, does a good job in self-protection, and invests with full enthusiasm. to rig service work.

In order to effectively ensure the quality of after-sales service work and the safety of employees, BOMCO has established a service guarantee working group led by leaders. It maintains close contact with the service team every day, communicates and coordinates with users, and provides necessary material support in a timely manner.

In November, the East Africa was still in full swing with the scorching sun. In order to ensure the progress of the drilling rig installation, the service team communicated and coordinated with the customer's on-site responsible team every day, and devoted themselves to the work. Everyone sweated and raced against time to exchange drilling rig installation experience with customers, overcome various difficulties, and ensure that work is completed every day with a clear division of labor and tacit cooperation.

On the well site, BOMCO employees sweated and worked together. They were busy everywhere in the pump area, machine room, backstage, drilling floor, derrick, ground, and high-altitude trucks. They dragged their tired bodies to the end until the dead of night. A busy day of work.

As the technical leader of the team, Wang Jingxiang carefully studied the design drawings, sacrificed meal breaks and repeated discussions with users. After repeated demonstrations, he proposed a number of on-site emergency treatment methods, solved on-site problems in a timely manner, and accelerated the assembly speed.

Gou Chaofeng and Li Xiaopeng, the drilling rig testers, were full of sweat on the assembly site. They were in charge of assembly and debugging.

Yang Fengbo, the person in charge of the site, carefully checked the daily assembly plan and kept in touch with users at any time. He was busy at the site during the day, and worked out the work plan for the next day at night, which efficiently handled many emergencies on the site.

In the kingfisher oilfield, the BOMCO after-sales service team was conscientious and hard-working, and completed the lifting of the drilling rig in just over 40 days, which won precious time for the subsequent debugging of the drilling rig, and made the first set of 8000-meter silent automatic drilling rig made in China stand tall. East Africa. Editor / Xu Shengpeng

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~