- GWH252-16MW ultra large capacity offshore wind turbine with a unit capacity of 16MW

- GWH252-16MW ultra large capacity offshore wind turbine with a unit capacity of 16MW

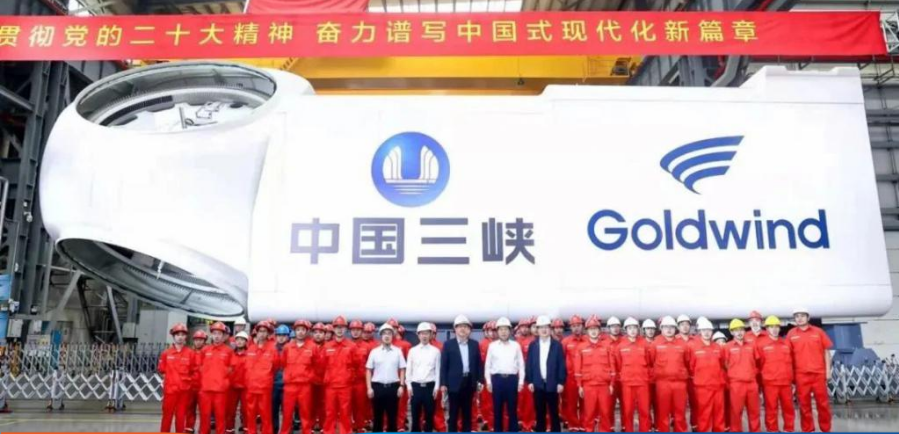

On November 23, 2022, the GWH252-16MW offshore wind turbine unit jointly developed by Goldwind Technology and Three Gorges Group and provided by Sichuan Resources with a full set of water cooling system was successfully launched in Fujian Three Gorges Offshore Wind Power International Industrial Park. This unit has once again set new records for the world's largest single unit capacity, the world's largest impeller diameter, and the lightest weight per megawatt.

Site of offline ceremony of 16 MW offshore wind turbine

GWH252-16MW super capacity typhoon resistant offshore wind turbine has completely independent intellectual property rights, and successfully overcome a series of key technical problems such as super long flexible blades, localization of large main shaft bearings, and miniaturization of super capacity generators. The successful launch of the unit marks a historic leap forward for China's offshore wind power equipment industry from scratch to existence and from existence to excellence, creating a new benchmark for the development of global offshore wind power equipment, and will help China's offshore wind power industry ride the waves and go steadily to the future.

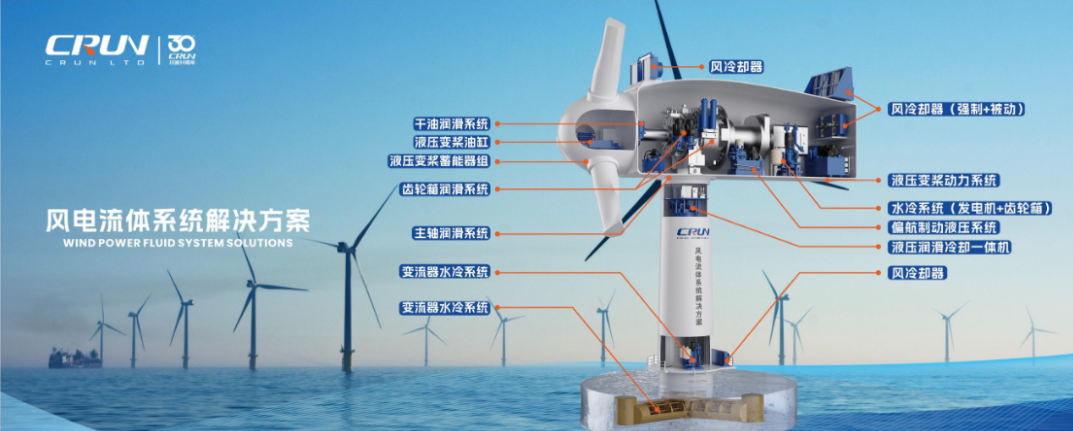

As the core equipment supplier of Goldwind Technology, Sichuan Resources has provided a complete set of cooling systems for GWH252-16MW offshore wind turbines, including electric drive water-cooled host, mechanical drive water-cooled host, unit external cooling radiator, high-level water tank, engine room radiator and unit central cooling pipeline.

Chuanrun adheres to the drive of scientific and technological innovation, and continues to seize the commanding heights of wind power fluid control technology. GWH252-16MW offshore wind turbine has the characteristics of large single unit capacity, high equipment heat consumption, poor marine corrosion environment and high equipment maintenance cost, which poses a great challenge to the comprehensive performance of the unit cooling system. In order to ensure that the unit R&D is completed on schedule, after receiving the notice of project startup, Chuanrun immediately arranged the design engineers to go to the research and development headquarters of Jinfeng Beijing for joint research and development. In the process of product design and prototype production, technicians from both sides exchanged views extensively, carried out model analysis, and strictly controlled the details. Every time a technical or quality deviation is found, corrective measures are quickly formulated and implemented, which ultimately ensures the first-class quality and performance of the product.

In order to meet the cost challenge in the era of wind power parity, Sichuan Resources has extremely controlled the product cost at the request of Goldwind customers. In combination with the cost reduction experience of previous projects, CR has adopted the design concept of minimalist structure and extreme performance in the new scheme conception process. Through more than ten simulation and verification calculations, it has achieved the external cooling and heat dissipation scheme with the lowest cost and the best performance, and finally achieved the full set of water cooling system scheme with the lowest comprehensive cost within the unit power generation.

In the process of prototype production, verification and production delivery, CR spared no effort to solve all difficulties. The prototype was manufactured and verified at the time of high temperature power limitation in Chengdu, and Sichuan Resources timely adopted the mode of off peak power consumption at night for production and verification testing. Then, the epidemic situation in Chengdu was closed down, and all project members volunteered to stay in the company for closed-loop production, ultimately ensuring the smooth delivery of the full set of water cooling system of wind turbine. After the delivery of products, Chuanrun also actively arranged technical and after-sales personnel to the customer's site for more than 20 days of on-site commissioning and guidance, which was highly recognized by the customer.

The wind is coming from the sea, and the tide is setting sail. In the future, as offshore wind power gradually moves into the deep sea, the power generation advantages and economic advantages of intelligent super large capacity units will be further highlighted. CR will continue to practice the corporate mission of "quality makes industry beautiful", take customers as the center, do a solid job in technical innovation, strengthen equipment research and development, and contribute to the new journey of helping China's offshore wind power industry achieve all-round transcendence!

The GWH252-16MW ultra large capacity offshore wind turbine unit, with a unit capacity of 16MW, impeller diameter of 252m and impeller sweep area of about 50000 square meters, is equivalent to the area of seven standard football fields. Under the full wind speed, 34.2 kilowatt hours of electricity can be generated per revolution. A single unit can output more than 66 million kilowatt hours of clean electricity every year, which can meet the normal power consumption of 36000 households with three people in a year. It can reduce the consumption of coal by 22000 tons and the emission of carbon dioxide by 54000 tons, with significant energy saving and emission reduction effects. The successful development of GWH252-16MW ultra large capacity anti typhoon offshore wind turbine has built a new milestone in the wind turbine equipment manufacturing industry. Editor/Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~