- Kaliwa Dam Project will supply 600000 cubic meters of domestic water per day to Manila, Philippines

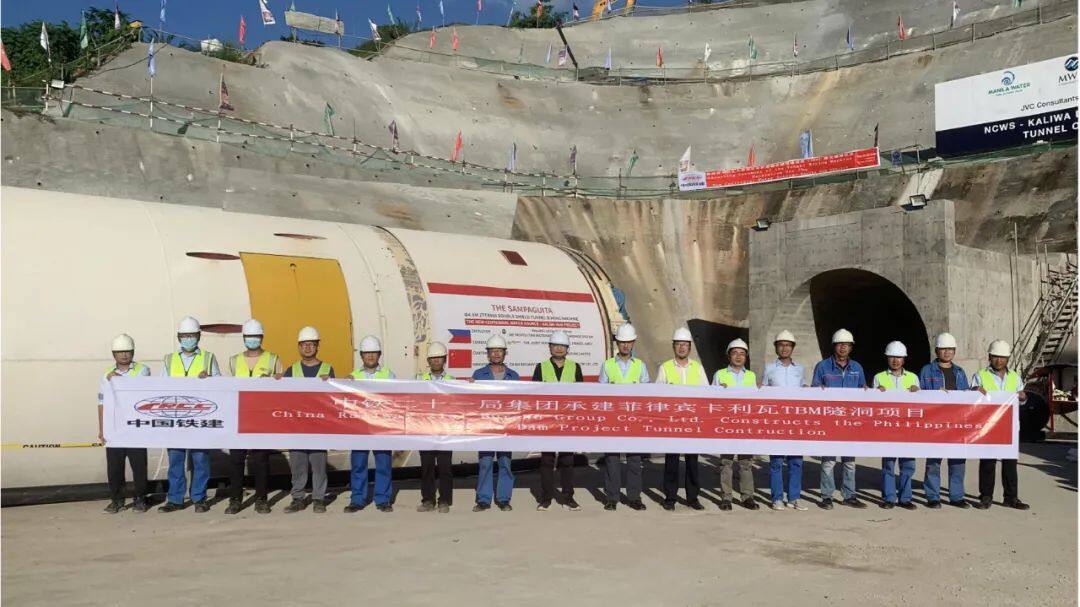

On December 7, 2022, with the roar of the machine and the slow rotation of the cutter head, the Philippine Kaliwa Dam Project "Jasmine" double shield hard rock tunnel boring machine participated by China Railway 21st Bureau successfully started.

The Kaliva Dam Project is located in Lecha Province, Philippines. As a major infrastructure construction project jointly signed by the heads of state of China and the Philippines, it is one of the flagship projects of the "Great Construction and Special Construction" plan in the Philippines. China Railway 21st Bureau is responsible for the construction of the 21.495 km headrace tunnel and the corresponding ancillary works, which is the key control project of the project. Among them, the shield tunneling is about 17.5km long, crossing 13 fault fracture areas, and the local section is karst development area, with karst caves, water gushes, mud inrush, relatively developed structural fissures, weak surrounding rock structure, and prone to deformation and damage.

The "Jasmine" launched this time was independently developed and produced by CRCC Heavy Industry. It is China's first hard rock tunnel boring machine exported to the Philippines with fully independent intellectual property rights. The shield machine has an excavation diameter of 4.8m, an installed power of 3800kW, a total length of 372m and a total weight of 1000t. It is truly a "steel pangolin".

In view of the unfavorable geology of the tunnel, the construction participants changed the traditional drilling and blasting method of tunnel construction, innovated the use of double shield hard rock tunnel boring machine, comprehensively used the equipment's ultra-high pressure escape propulsion system, advance drilling and advance geological prediction system of the tunneling machine and other advanced technologies to carry out construction, and accelerated the high-quality, rapid and efficient construction of the project. In addition, in accordance with the construction method of "early detection, pre grouting, fast sealing, first plugging and then discharging, and controlled discharge", they also did a good job of advanced detection and pretreatment. Focusing on water sealing, they adopted curtain grouting consolidation, advanced pre support, flow limiting grouting and other methods to prevent water and mud gushing and improve the stability of the tunnel.

Since coming into operation in June 2021, the construction personnel of China Railway 21st Bureau have overcome the difficulties such as the impact of the COVID-19, the lack of local construction and production resources, the different construction standards, and the tropical rainforest climate, and assisted the owner in completing the land acquisition and site survey at the departure point of the tunnel exit shield machine. In order to meet the requirements of the Owner for the starting node of the shield machine, the relevant leaders of China Railway 21st Bureau led the team to stay at the project site, transferred elite and powerful personnel from home, strengthened the professional technical force, urged and tracked the process of handling various construction permits, promoted the access of municipal power, accelerated the assembly speed of the shield machine and the progress of segment production, established mutual trust and cooperation with local material and equipment suppliers, and created emergency procurement conditions for small tools, instruments, spare parts, etc, Effectively and orderly promote project construction and production.

It is reported that the Kaliwa Dam, as an important part of the Philippines' new century water source plan, has a design capacity of 57 million cubic meters. After completion, 600000 cubic meters of domestic water will be supplied to the Manila region of the Philippines every day to completely solve the problem of water shortage in the Manila region, with significant economic, social and ecological benefits.Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~