- The clean and efficient utilization of coal includes two aspects, the first is source emission reduction

- The second is to vigorously carry out the research and development of pollution reduction and carbon reduction technologies including CCUS, etc., and strengthen pollution control

Recently, the reporter interviewed Wang Jie, deputy to the National People's Congress and Zheneng Group. She said that the environmental protection facilities of coal-fired boilers of coal-fired power units are like the briquette stoves used at home in the past. An ordinary mask is worn at the outlet exhaust position to remove harmful gases, and the ultra-low emission is equivalent to wearing a KN95 mask. Upgrade the mask, and the exhaust gas is cleaner.

Wang Jie introduced to the reporter that the ultra-low emission technology of coal-fired units is based on the original environmental protection facilities of coal-fired units, and uses a variety of pollutants to efficiently and co-process a removal technology. Specifically, based on the emission technology of traditional coal-fired units, a series of technologies such as wide temperature window denitrification technology, low and low temperature electrostatic precipitator technology, wet electrostatic precipitator technology, desulfurization and efficiency improvement are further adopted to improve the removal level of pollutants . After using this technology, the concentration of main pollutants in the flue gas discharged into the atmosphere, such as soot, sulfur dioxide, and nitrogen oxides, shall not exceed 5 mg, 35 mg, and 50 mg per cubic meter respectively, reaching the level of pollutants from natural gas generating units. emission levels. In addition, mercury, sulfur trioxide and PM2.5 in the flue gas are further removed.

National People's Congress Representative, Zheneng Group Wang Jie

In recent years, Wang Jie has actively organized the research and development of projects such as pollutant control in coal-fired power plants and operation optimization of environmental protection equipment, and participated in the ultra-low emission testing and optimization of coal-fired units. Wang Jie told reporters that the ultra-low emission technology of coal-fired units has been fully promoted, and the localization rate of ultra-low emission equipment has reached 100%, which has got rid of the dependence on technology and equipment from Japan, the United States, Europe and other countries. In the next step, the technology will be further upgraded and extended to other industries such as steel and ships.

The power generation cost of coal-fired power plants is equivalent to 1/3-1/2 of the cost of natural gas power generation. The application of ultra-low emission technology for coal-fired units has enabled coal-fired power generation to reach the pollutant emission level of natural gas power generation. Wang Jie said that, on the one hand, ultra-low emission technology has broken the traditional concept that coal-fired power plants are major sources of pollution; The cleanliness of electricity has expanded new space for coal-fired units, improved the level of clean and efficient utilization of coal from the end treatment, and helped China's energy green and low-carbon transformation and high-quality energy development.

Regarding how to realize the clean and efficient utilization of coal, Wang Jie further pointed out that there are mainly two dimensions: from the source, it is necessary to actively promote the transformation of coal power generation to clean, low-carbon, flexible and efficient. For example, the linkage of the three reforms of existing units and the construction of new high-parameter and large-capacity units will further improve the clean and efficient power generation capacity of coal power, and at the same time meet the demand for electricity in the process of rapid economic development.

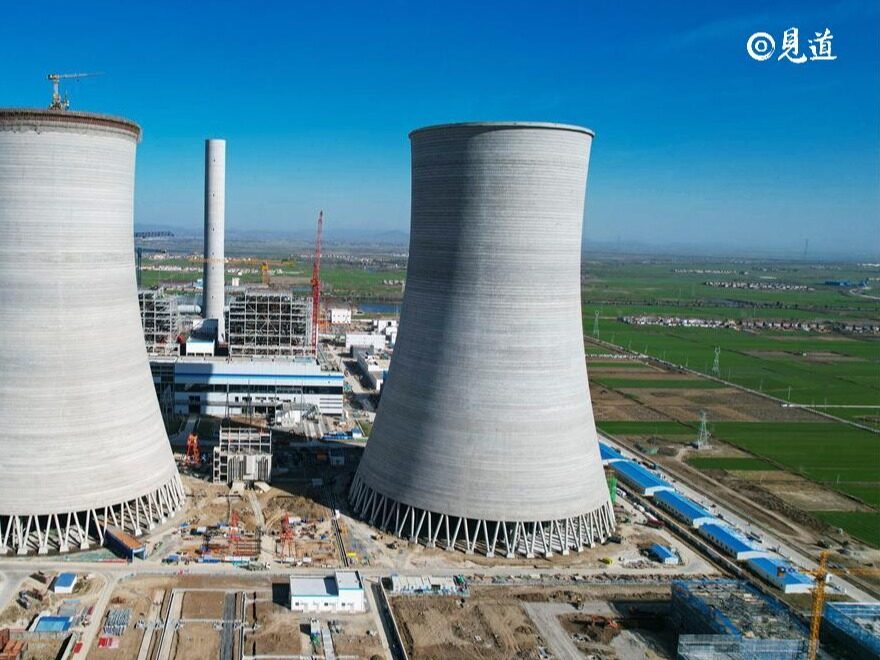

Zheneng Taizhou Second Power Generation Company ultra-low emission device

From the perspective of governance, it is necessary to vigorously carry out research and development of ultra-low emission and pollution reduction and carbon reduction technologies. For example, the 10,000-ton CCUS carbon capture, utilization and storage project built by Zheneng Group in Lanxi Power Plant is the first coal-fired carbon capture and mineralization utilization full-process coupling project in China, realizing high efficiency, low energy consumption, and synergy of carbon dioxide capture The goal of waste gas pollution control has developed a new generation of carbon dioxide capture technology and mineralization maintenance technology. At present, the project has entered the commissioning stage. After completion, the carbon dioxide capture capacity can reach 15,000 tons per year, and the carbon dioxide derivatives produced by it will be widely used in many industrial fields. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~