- The rated lifting moment of the Tower crane is 8250 tons/m, and the maximum lifting capacity is 320 tons

- The tower crane integrates 58 innovative scientific research achievements and 106 patented technologies, including more than 60 core key technologies

On June 15, the R8000-320 Tower crane jointly developed and developed by China Railway Construction Corporation Bridge Bureau and Zoomlion Heavy Industry Science and Technology Co., Ltd. was successfully launched, which will help the lifting and construction of the steel tower section of Zhangjiang Jinggao Yangtze River Bridge, the world's largest span Suspension bridge built by the group. The lifting capacity of the Tower crane ranks the fourth in the world, and it is the largest tonnage Tower crane of China Railway Construction Corporation at present. The delivery and use of the weight of China Railway Construction Corporation will greatly enhance its Hard power in bridge construction.

Iron construction heavy tools showcase a unique and towering appearance

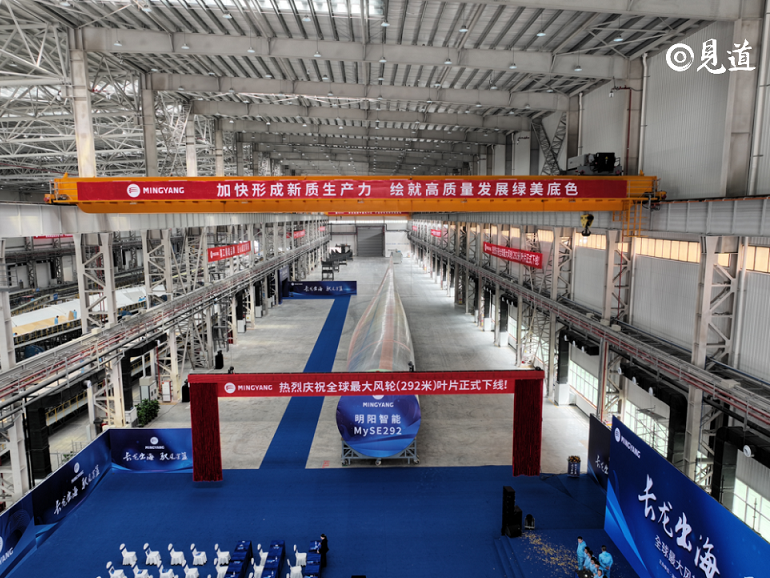

R8000-320 Tower crane made a wonderful appearance at the offline delivery ceremony held in Changde, Hunan. At the first lifting site of the equipment, a 5G remote control trial lifting was also achieved for the first time at the Tianjin branch venue 1500 kilometers away. The rated lifting moment of the Tower crane is 8250 tons · m, the maximum lifting capacity is 320 tons, and the maximum lifting height is 400.3 meters, which is equivalent to lifting 230 cars to 130 floors at one time. The upper part of the tower crane is equipped with L250-20 boom tower crane, the maximum lifting capacity is 20 tons, and the installation arm is 40 meters long, which can cover the maintenance of the lifting mechanism of R8000 Tower crane and the installation and removal of the attachment frame.

If you want to do good work, you must first sharpen your tools. The Group's investment in the construction of super large Tower crane will add diamond for enterprise bridge construction, accumulate equipment for the Group to build a bridge brand, and greatly enhance the professional strength of bridge construction.

Excellent performance, surging intelligent construction force

Jointly developed by China Railway Construction Corporation Bridge Bureau and Zoomlion Heavy Industry Co., Ltd., R8000-320 Tower crane has excellent lifting performance, leading structural technology in the world, and integrates high-end, intelligent and green technologies. The tower crane integrates 58 innovative scientific research achievements and 106 patented technologies, including more than 60 core key technologies. It not only achieves strong lifting performance of the tower crane, but also ensures safety, convenience, and reliability in transportation, installation, dismantling, operation, and maintenance.

The Tower crane is a configuration of one tower and three cranes with main and auxiliary towers coexisting, which can realize coordinated hoisting of main and auxiliary towers, with efficient use and convenient maintenance; With strong modular design, it can achieve a lifting performance of 12000 tons per meter with only 5% replacement of components, and the lifting performance is improved by 50%; There are more than 150 monitoring points of the whole machine, and more than 80 intelligent technologies have been created. The tower crane synchronously realizes a number of intelligent control technologies, such as anti-collision, anti slip hook, anti-collision, anti lifting anchor, hook inclination detection and early warning, to comprehensively ensure construction safety and efficiency; Equipped with the latest intelligent lifting high-precision matching measurement and control system, achieving precise lifting; Build a smart command center to assist in the remote and digital management upgrade of equipment.

Heavy weapons launched to assist in building world-class bridge projects

After being delivered to China Railway Construction Corporation Bridge Bureau, the Tower crane will be mainly used in the construction of the world's largest span Suspension bridge - Zhangjinggao Yangtze River Bridge. According to Zhang Hui, the project leader of the north channel bridge of the Zhang Jinggao Yangtze River Bridge, "the north channel bridge adopts a portal structure steel tower with a total height of 217 meters, which fills the gap in the performance of steel towers of China Railway Construction Corporation Suspension bridge. The tower crane is used to hoist the steel tower sections, which requires 6057.4 tons in total, and the lifting is planned to be completed in 12 months." The Zhang Jinggao Yangtze River Bridge is a river crossing channel that will be promoted during the 14th Five Year Plan period, It is also a key implementation project for the comprehensive three-dimensional transportation corridor planning of the Yangtze River Economic Belt in Jiangsu Province.

At the same time, R4300-200 Tower crane was delivered, which will be used in the construction of Wusong high-speed Guanyinsi Yangtze River Bridge, the world's largest span highway cable-stayed bridge participated by China Railway Construction Corporation Bridge Bureau. The rated lifting moment of Tower crane is 4300 tons · m, the maximum lifting capacity is 200 tons, the independent height is 102 meters, and the maximum lifting height is 415.3 meters, which is another sharp tool for bridge construction of the group.

At present, the Group has more than 50 sets of special bridge construction equipment, such as super large Tower crane, high-speed railway box girder lifting frames, crane boats, etc. Among them, the first large crane ship of China Railway Construction Corporation, the 2200 ton crane ship No.1 of China Railway Construction Bridge, plays a role of a water giant in the construction of the Fourth Macao Taipa Bridge. In the future, large-scale equipment such as a 1000 ton fully rotating crane ship and a concrete mixing ship will also be purchased. Develop specialized equipment on large-scale special bridge projects to provide strong equipment support for the safe, high-quality, and efficient completion of the construction of high-precision and difficult to navigate super large bridges. Editor/Xie Li

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~