- SET240S electric wheel mining vehicle saves more than 15% energy compared to traditional electric wheel mining vehicles

- SET240S electric wheel mining truck can meet various working conditions in open-pit mines

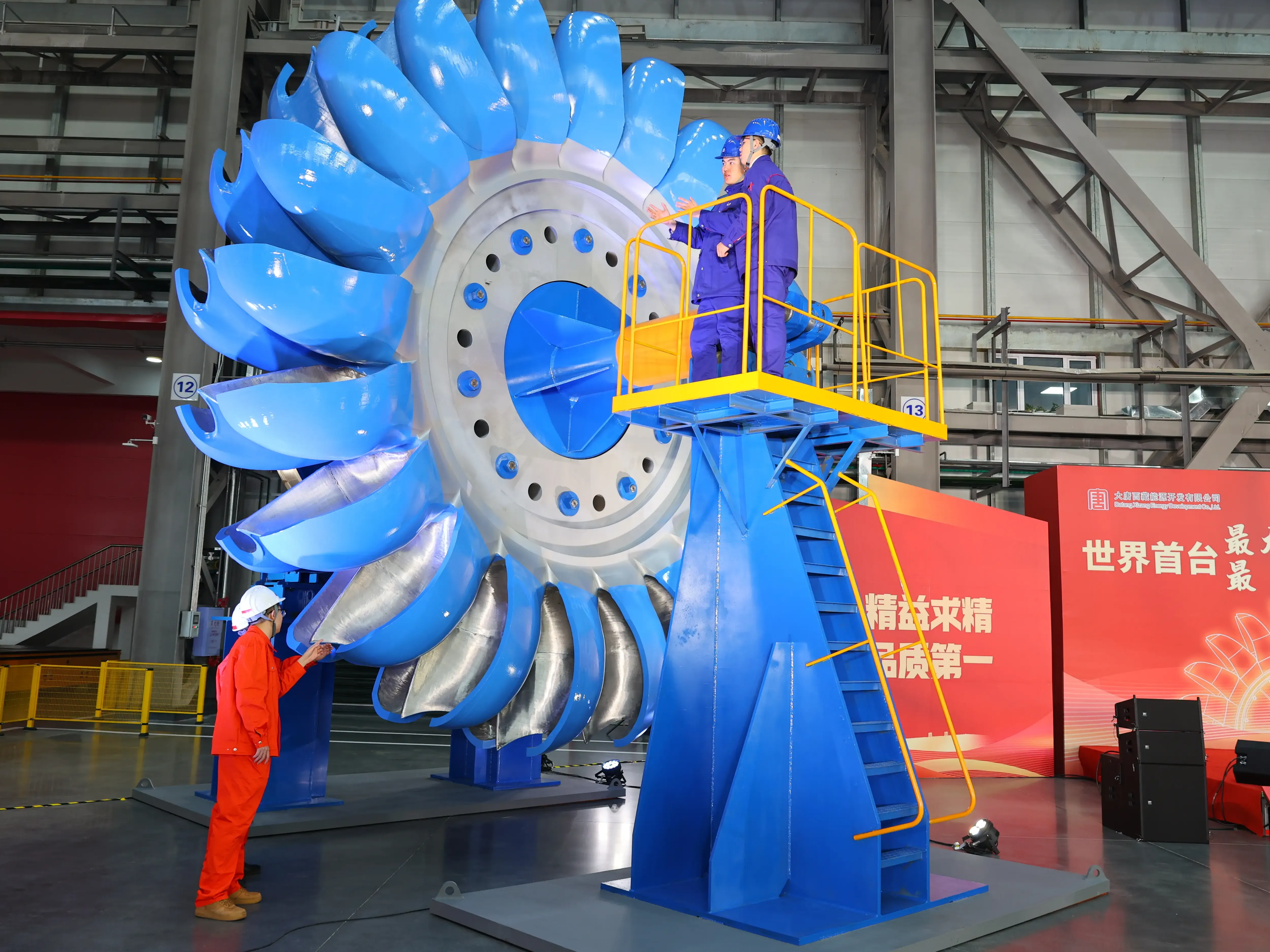

Recently, the Sany hybrid energy-saving SET240S electric wheel mining vehicle was officially put into offline acceptance at the Sany Heavy Duty Shenyang Industrial Park. Mr. Qi Jian, Chairman of Sany Heavy Industries, Mr. Qu Xiaofei, General Manager of Sany Heavy Industries, and Mr. Huang Xianhui, President of Sany Heavy Industries Mining Vehicle Research Institute, attended the event and conducted acceptance review work.

Zhou Xu, deputy director of the Electric Wheel Overall Institute of the Mining Vehicle Research Institute, introduced that the SET240S electric wheel mining vehicle is the first three engine hybrid off-road mining Dump truck in the industry. Compared with the traditional electric wheel mining vehicle, it can save energy by more than 15%, reduce maintenance costs by more than 50%, and create greater value for customers.

Vehicle Introduction

High transportation capacity: Adopting a three engine system (3 × 565kW) combined with a 396kW power type battery pack (79.5kW · h, 5C), the total power of supermarket products of the same tonnage is 12%, and the heavy-duty climbing speed is fast, increasing the comprehensive transportation capacity by more than 10%.

Low maintenance cost: Replacing high-power engines with small engines reduces overhaul costs by 50% and maintenance costs by 20%.

High safety: 360 look around, Automatic fire suppression, automatic weighing, tire pressure and tire temperature monitoring system, and cluster anti-collision system can be configured to improve safety. The cab has FOPS/ROPS certification and good protective performance; Adopting 3C certified safety seats. High power electric braking+hydraulic braking dual braking, with superior braking performance.

High reliability: A brand new enclosed, frame structure frame, with large cross-section box shaped structure for the left and right longitudinal beams, improving torsional resistance. The frame has a lifespan of more than 15 years. The design of a large channel cooling structure solves the heat dissipation problem of the driving motor under each working condition.

High intelligence: Equipped with working condition recognition technology, adaptive cruise control+engine optimal curve control. Vehicle CAN bus design+GPS system, real-time remote monitoring of vehicle operation data. Vehicle fault diagnosis and troubleshooting time increased by more than 10% compared to competitors. Remote query and monitoring of vehicle operation data through mobile app.

The SET240S electric wheel mining vehicle, which took one year from investment in research and development efforts to complete the production line, is currently a major model independently developed and produced by Sany Heavy Industries, and can meet the usage needs of various working conditions in open-pit mines.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~