- Signifies a significant breakthrough in the manufacturing technology of mooring systems for deep water oil and gas field development

- The design mooring load of a single suction anchor is 2500 tons, with a height of 22 meters, a diameter of 6.5 meters, and a depth of 21 meters into the mud

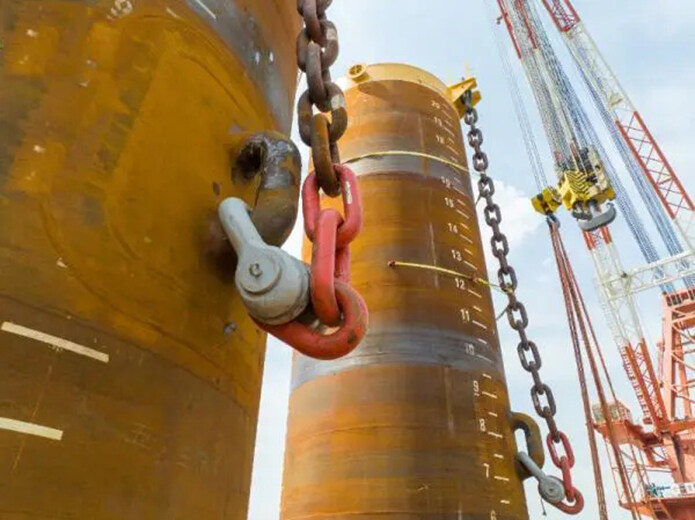

It is reported that the cylindrical FPSO deep water suction anchor, which has the deepest mud entry and the largest mooring load in China, for the secondary development project of the Liuhua 11-1/4-1 oilfield, has been delivered for shipment at the special equipment manufacturing site of Tianjin Offshore Oil Engineering. For the first time, its core load-bearing component, the casting lifting lug, was completely designed and constructed by China, marking a significant breakthrough in China's manufacturing technology for deep water oil and gas field development mooring systems.

The suction anchor is the core equipment of the mooring system for deepwater oil and gas field floating facilities, and is known as the anchor for FPSO to settle in the ocean. It is composed of a cylinder, top cover, casting lifting ears, anchor head chains, etc. It is like a large steel suction cup. By installing a suction pump on the top of the anchor, there is a pressure difference between the inside and outside of the anchor, firmly adsorbing itself in the deep sea mud, and firmly anchoring the FPSO in the sea like a mooring pile. The cylindrical FPSO of the Liuhua project adopts a multi-point mooring method and is moored to the seabed through 12 sets of suction anchors. The design mooring load of a single suction anchor is 2500 tons, with a height of 22 meters, a diameter of 6.5 meters, and a depth of 21 meters into the mud. It can adsorb 1700 cars on the seabed. Editor/Xie Li

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~