- The total investment of this project is about 3 billion yuan, and it can achieve an annual output value of 5.2 billion yuan

- The second new, third high, second low, and no three waste iron phosphate products produced by this project are mainly used for the production of lithium iron phosphate and lithium manganese iron phosphate materials

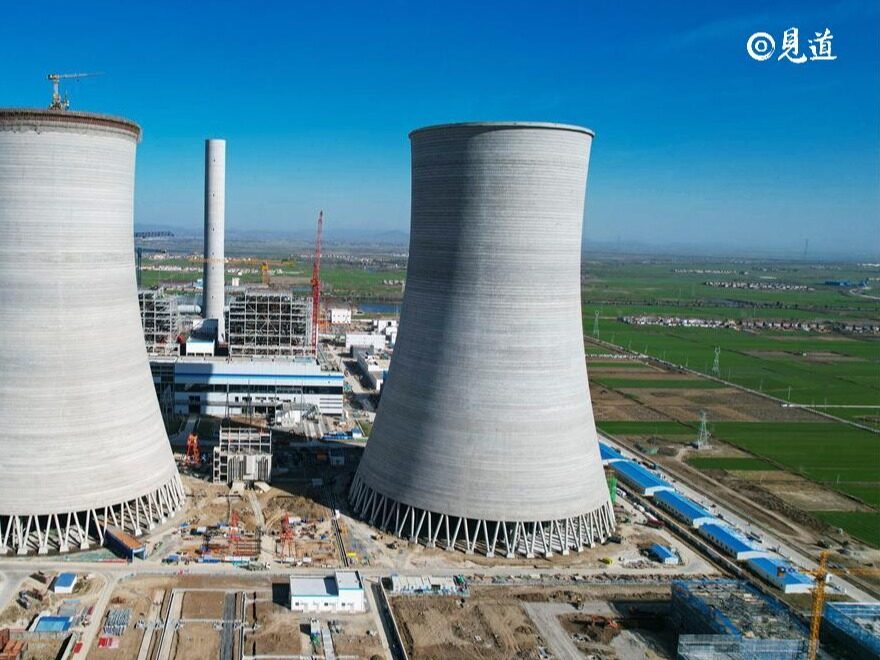

On the morning of August 16, 2023, the first domestic green process, low-temperature high-performance lithium iron phosphate precursor 400000 tons of iron phosphate project, Phase I, began construction in Binzhou.

It is understood that the total investment of this project is about 3 billion yuan, covering an area of 168 acres. The second new, third high, second low, and no three waste iron phosphate products produced by the project are mainly used for the production of lithium iron phosphate and lithium manganese iron phosphate materials, used for new energy vehicle batteries and energy storage batteries. After completion and production, it can achieve an annual output value of 5.2 billion yuan and achieve an annual profit and tax of 1.7 billion yuan. At the same time, the project will bring higher performance, higher stability, lower cost, and more environmentally friendly iron phosphate products to the market, contributing to the promotion of higher quality development in industries such as new energy vehicles.

Iron phosphate is one of the main raw materials for producing lithium iron phosphate cathode materials. With the rapid development of new energy vehicles and energy storage industries, the demand for lithium iron phosphate has also shown explosive growth, and the supply of its precursor iron phosphate has also shown a high growth situation, forming a structural overcapacity, insufficient high-end production capacity, and overcapacity at the middle and low end.

In this context, Jiuhuan Energy Storage Technology Co., Ltd. is steadily promoting its existing industry and actively responding to the national "dual carbon" strategy and the requirements of Shandong Province for the conversion of old and new energy, vigorously developing new energy storage industries. The scientific research team led by Li Changming and Xin Minchang, after 5 years of innovative research and development, has launched the first domestic new production process for iron phosphate and a new material system for iron phosphate precursors. This process not only produces iron phosphate, but also produces export grade high value-added product salt in equal quantities. The salt has high purity and can be directly used for metallurgical industry production, resulting in huge demand in overseas markets. Editor/Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~