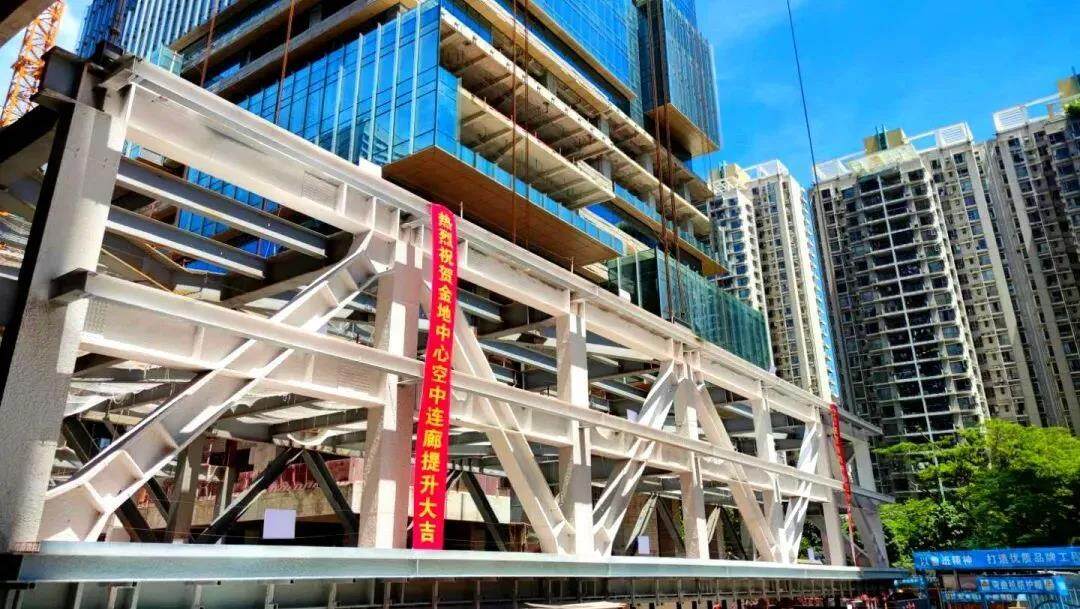

- Tower A of Shenzhen Golden Land Center is 199.5 meters high, Tower B is 159 meters high, and Tower C is 35 meters high

On June 22, 2020, the Shenzhen Gemdale Center project undertaken by the China Construction Third Engineering Bureau and the Shenzhen Golden Land Center project was upgraded in place. It was the first domestically-oriented Z-type super high-rise cantilevered large-span overall lifting steel corridor.

The connected structure has a north-south span of 94 meters and an east and west cantilever span of 19.4 meters. It consists of 5 cantilevered trusses and 770 steel beams. The maximum weight of the single truss is 112 tons, the overall lifting weight is 1670 tons, the total weight is 2300 tons, and the lifting height is 150 meters.

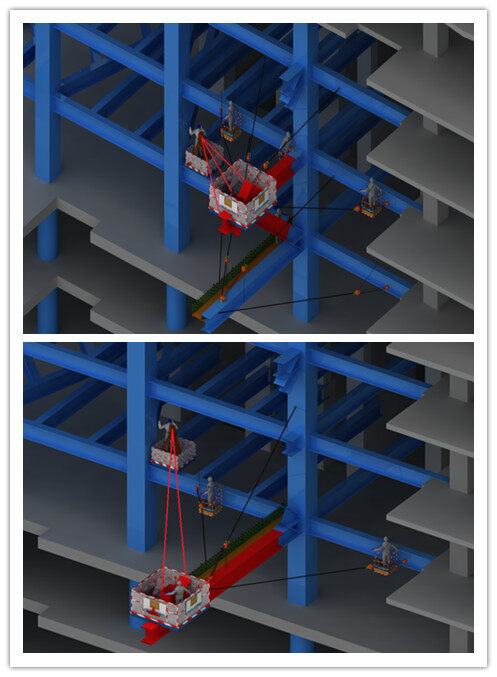

The project team is scientifically organized and carefully prepared. According to the structural form of the air corridor, the connection part of the arc truss and the inner ring truss is installed by the hydraulic integral lifting construction method, and the "integrated ground assembly + high-altitude truss scattered assembly + overall lifting + high-altitude secondary beam scattered assembly" The combined construction plan uses 12 lifting points to raise it to the design elevation, with a lifting height of 150 meters, for a total of 49 hours.

The complete set of high-intelligence promotion platforms and monitoring systems for the application of this corridor upgrade are the leading domestic level. The implementation of this process greatly reduces the difficulty of high-altitude lifting, and has accumulated a lot of practical experience for scientific and technological construction and green construction.

Coming together with innovation

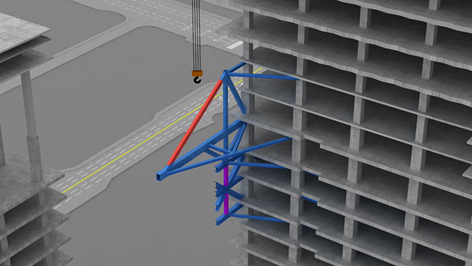

Utilizing the permanent structural stiff steel columns and steel beams of the two towers, we have developed a stiff column tower body, a 20-meter steel structure cantilevered lifting boom, a stiff beam balance arm and a balanced steel vertical column. Type lifting structure, the overall force transmission path is clear, safe and economic.

High-precision "dual control" measurement

Due to the large span of the steel structure, complex structural nodes and self-importance of the project, temperature deformation and load deformation have a great influence on the installation of the steel structure, and the load will continue to change during the cantilever construction process, so the intelligent total station is used to carry out the space of the components Three-dimensional coordinate measurement, using GPS global satellite positioning technology to check the reference point position, to ensure that the corridor structure under the "dual control" of the two measurement technologies to achieve rapid and high-precision installation.

Computer synchronization control system

Aiming at the 2300 tons dead weight Z-shaped cantilevered corridor structure, the lifting points are scientifically and rationally arranged according to the principle of central symmetry, and through SAP2000 modeling and review analysis, the positioning and number of lifting points are continuously compared and verified, and finally the design of 12 lifting points is determined. The scheme uses the TL-CS 11.2 computer control system to intelligently upgrade the corridor.

The control system adopts travel and displacement sensor monitoring and computer control. Through data feedback and control command transmission, it can fully realize synchronous action, load balancing, posture correction, force control, operation blocking, process display and fault alarm. . The operator can observe the hydraulic lifting process and related data and issue control commands through the hydraulic control computer control system man-machine interface in the central control room.

The project is located in Nanshan District, Shenzhen, and consists of three towers, A, B, and C. Tower A is 199.5 meters high, Tower B is 159 meters high, and Tower C is 35 meters high. The podium is distributed on the second and third floors between AC and BC, and the air corridor is distributed between 35F-37F of A and B buildings. Upon completion, it will become a landmark building in the core area of Shenzhen Nanshan Science and Technology Park and a future headquarters office base of Gemdale Commercial Group. Editor/Peng Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~