- In the global technology system, chip manufacturing has the ultimate meaning

Due to the US ban, foundry companies such as TSMC and SMIC, which use US technology, will no longer be able to produce chips for Huawei after September 2020. Recently, it has been reported that Huawei is hiring people to develop lithography machines and that Huawei will build its own chip production line. Although these news cannot be confirmed, the technological war between China and the United States is clearly intensifying.

If you think deeply, you will ask: Why are these messages concentrated on the chip? What are the weaknesses of China? Will the United States launch attacks in other areas?

In 2018, "Science and Technology Daily" summarized 35 "stuck neck" technologies, and these technologies have considerable representative significance. The most of these 35 items are chip-related technologies, including 6 items: chip, photolithography machine, photoresist, radio frequency chip, ultra-precision polishing process, and industrial software. The standards for this classification are obviously not uniform. There are large categories such as chips and small categories such as radio frequency chips.

The second most is the technology related to aircraft, including 4 items: aero engine cabin, airworthiness standards, aviation design software, and aviation steel. If the United States wants to expand its suppression of China, the aircraft industry is an important area. However, the importance of the aircraft industry is not as important as the chip, because its influence will not spread to other industries. In addition, the aircraft industry is not the only one in the United States, but a dual-headed structure of the United States and Europe. Therefore, even if the United States wants to "troubleshoot" the Chinese aircraft industry, its destructive power is greatly limited.

The third most is software, which includes two items: operating system and database management system. These are core technologies dominated by the United States, but the threat is still far inferior to chips. There are so many people and companies that can write these software. The real question is how many people are willing to use it, that is, the ecological environment.

There is a broad road, open source software. For example, the open source Linux operating system and MySQL database have been widely used. Ali's OceanBase database is derived from open source software, and after a lot of innovation, it has become an independent and controllable core database.

The other 20 items are basically single technologies in a single field, such as tactile sensors, vacuum evaporation machines, heavy-duty gas turbines, lidars, robotic core algorithms, special milling cutters, high-pressure plunger pumps, and high-pressure common rail systems. These technologies are of course valuable, but the ability to "stuck the neck" is even less comparable to the previous ones. And look carefully, the United States does not have many advantages, only a few such as lidar and medical imaging equipment, while Japan, Germany, and Sweden have many advantages.

Some technologies were listed as "stuck neck" technologies in 2018, but they are no longer counted. For example, high-end bearing steel, China's high-speed rail bearings are now "made in Luoyang", domestic high-end bearing steel is also exported to Japan and Europe. Another example is high-end resistors and capacitors. In this regard, Japan is dominant, but China can also manufacture them. The quality of batches produced in China is not neat enough, so manufacturers are more willing to purchase Japanese products with neat quality. But if Japan cuts its supply, domestically produced products will be able to top it. Another example is microspheres. In 2019, the microspheres produced by Suzhou Nanotech broke the Japanese technology monopoly, saving tens of billions of dollars each year. Another example is the special milling cutter. In May 2019, the leader of Foxconn's Shenzhen subsidiary ST tool saw the news that the domestic high-speed rail milling cutter was overwhelming, and arranged a task for five months to produce a domestic rail intelligent repair milling cutter. There are also radio frequency chips among the six chips, which have basically made a breakthrough, from raw materials to design, manufacturing, and nearly all localization.

In fact, China has made breakthroughs in many technological fields in recent years. For example, on May 10, 2020, the main bearing of the domestic roadheader passed the acceptance test. In the field of lithium battery separators, Enjie shares accounted for 50% of the global market share. In the field of underwater connectors, the watertight rubber-plastic gigabit transmission component developed by Lansuo Technology passed the acceptance in April 2019. In the field of carbon fiber epoxy resin, Guangwei Composites has developed from fishing rods to military carbon fibers, creating a miracle of technological development (the Sino-US science and technology battle (7)-the spiritual power of innovation | Wang Tao). In terms of high pressure common rail system, Weichai Power's domestically produced system was developed and launched in 2012. Therefore, a single technology is not enough to control the industry. What deserves the most attention is the system-level control, which is the control of the information industry by the United States, especially the control of the chip industry.

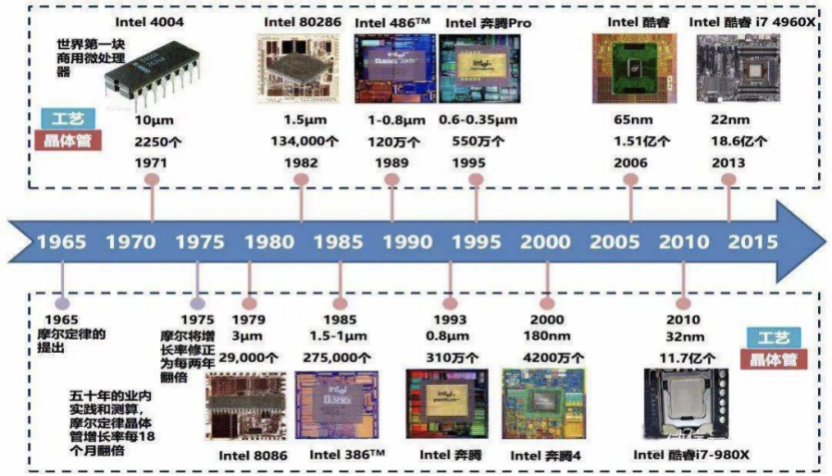

Why is the chip so special? Because its performance improves too fast. The chip industry has a famous "Moore's Law", that is, every 18 to 24 months, the transistor density of the chip will double. This speed is simply against the sky, much faster than other industries.

What needs to be explained is that "Moore's Law" is not a physical law, but an industrial plan that predicts future development based on historical experience, just like a "five-year plan." The giants of the chip industry chain will often meet to discuss how to achieve such a development speed, and coordinate to turn it from a goal into a reality. The direct consumers of chips are not ordinary people, but a large number of electronic product merchants. For example, when the epidemic situation is serious, the hot temperature measuring gun is sold, and the core device is the temperature measuring chip.

In the early 1990s, Huawei was at this level, incorporating the functions of program-controlled switches into the board and using chips. Few Chinese companies were able to do this at the time, but they are now cabbageized, and there are countless companies that can do this kind of development in Shenzhen alone.

The general technology at this level may be a printed circuit board (PCB), which interconnects various components such as chips and resistors on the board. To engage in development at this level can already do a lot of things, which is one of the main manifestations of China's technological competitiveness. Therefore, in the field of IT applications, the US's advantages are mainly concentrated in the Internet and movie special effects, while China is more active in consumer electronics.

The next level of IT applications is chip design, which is much more difficult. After the IT application writes the code, you can run the result debugging in a few steps. However, chip design has to go through many steps to produce results. The entire process is highly dependent on tool software, and the design and development costs of complex chips are getting higher and higher.

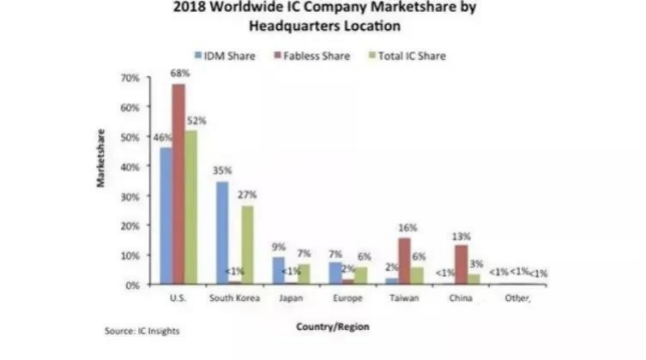

At the level of chip design, American companies have a much greater advantage. In 2018, the share of the world's integrated circuit market is as high as 52%.

In the figure above, the chip design patterns are divided into two categories. One type is self-designed and produced, which is called integrated device manufacture (IDM). The other is to design and invite others to produce. This is called a factory-less chip supplier, and the English is fabless. Huawei HiSilicon, MediaTek, Apple, Qualcomm, etc. are all fabless. Mainland China accounts for 13% of the fabless field, ranking third in the world. IDM is dragging its feet, and China has almost none. The result of the two is that China's overall share is only 3%.

In recent years, the number of Chinese chip design companies has grown rapidly. At the same time, due to the emergence of open source development platforms such as RISC-V, the threshold for designing chips has dropped. For example, five undergraduates from the University of Chinese Academy of Sciences, under the guidance of Dr. Bao Yungang, a researcher at the Institute of Computing Technology of the Chinese Academy of Sciences, and others, designed a 110-nanometer CPU chip in four months. Run up the Linux operating system.

Chip design giants like HiSilicon are advancing to the world's advanced level. However, to the next level, chip manufacturing is China's biggest shortcoming. Chip components are getting smaller and smaller, and the manufacturing process is as small as tens of nanometers or even a few nanometers, which is equivalent to one thousandth to one ten thousandth of a human hair. Not only is it easy to make mistakes, but it also encounters obstacles that cannot be circumvented by the old route and requires new technical principles. The requirements for R&D manpower, capital, and time are getting higher and higher, so that established manufacturers continue to withdraw from the competition.

For example, GlobalFoundries, once the world's second largest foundry in the United States, announced in 2018 that it had abandoned 7nm R&D. UMC, Taiwan’s second-largest foundry, announced earlier that it had given up. In order to "get off the burden", IBM sold the chip factory to GlobalFoundries for $1.5 billion in 2013. Intel has also been stuck in chip manufacturing in recent years, and the yield of the 7-nanometer production line has been slow to improve.

Only TSMC seems to have "opened up" and has chosen the right technology development direction many times. Mass production of 7nm and 5nm, 3nm and 2nm are also news. Now, only Samsung is still following TSMC.

Generally speaking, the technological route of chip manufacturing is becoming more and more difficult, the research and development spends more money, and the construction of production lines spends more money, and it may not be possible to spend money. Although chip design is difficult, there are still "players" joining in, and the number of "players" in chip manufacturing is decreasing rather than increasing. It can be seen that chip manufacturing is the most demanding manufacturing field.

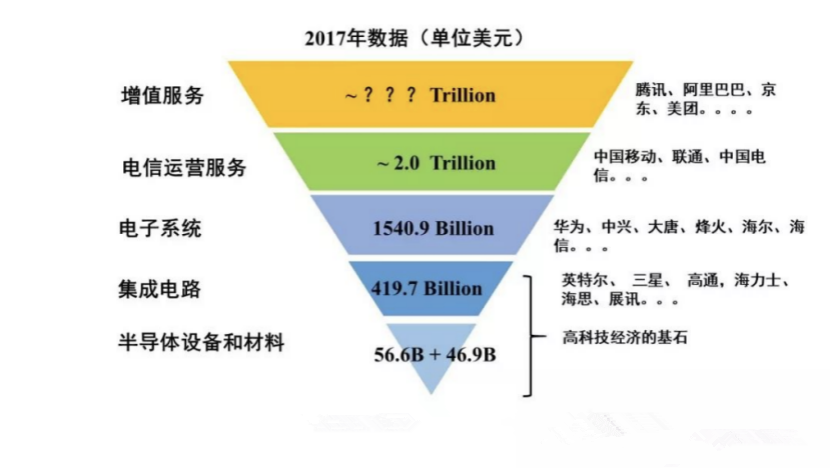

In the IT industry chain, China is doing well as a chip consumer, chip design is also on the rise, and chip manufacturing is the most difficult barrier at the end. In fact, as long as you understand the technical principles, you will understand that the sequence of China's development must be like this. Professor Wang Zhihua from the Institute of Microelectronics of Tsinghua University wrote an article "Applauding the development of China's communication technology and industry | Mr. Wang's wine restaurant" after the ZTE incident in 2018, and gave a picture in it. In an information society based on integrated circuits, the complete industrial chain is an inverted triangle.

The top level is the information value-added service industry, such as Tencent, Ali, Toutiao, etc. The scale of this level is huge, and there are many technologies that China is leading, such as WeChat, Alipay and Douyin.

The second layer is operators of information services, such as China Mobile, China Unicom, and China Telecom. The scale of this industry is also very large. It is estimated that the global telecommunications turnover in 2017 reached 2 trillion US dollars. At this level, China's operational level and technical level are synchronized with the world.

The third layer is communication equipment vendors, such as Huawei, ZTE, Cisco and so on. Those who came here in the 1980s will remember that China's communications were so-called "seven countries and eight systems", which was very backward. With the efforts of the "Communicators", Huawei has now become the number one in the world. This is a historic achievement.

The fourth layer is integrated circuits or chips, such as TSMC, Intel, Samsung and so on. The fifth layer at the bottom is semiconductor equipment and materials, that is, the equipment and materials needed to make chips, such as ASML for photolithography machines, Zhongwei Semiconductor for etching machines, and so on.

In this inverted triangle diagram, the higher the top level, the larger the scale and the more advanced China’s technology; the lower the bottom, the smaller the scale and the more backward China’s technology. For example, the fourth-tier integrated circuit industry has a global output value of about 420 billion US dollars in 2017, and China only accounts for 7%.

The basic reason for this phenomenon lies in the fact that the industries from integrated circuits downward are the products of the accumulation of achievements in the industrial society; the industries from integrated circuits upward are the emerging products of the information society. China has caught up with the information society and is developing simultaneously with other parts of the world, so it can take the lead locally. China has not fully experienced the industrial society, and we lack the accumulation of technology in the industrial society, so we need to make up lessons.

Generally speaking, China is "cannibalizing" from the top of the industrial chain to the foundation a little bit, just like the water, which is determined by history. So we must be patient and confident. The future is bright, and the road is tortuous.

Can we pass this level? The short answer is: in principle, it certainly works, because you already know it is feasible. Just as the biggest secret of the atomic bomb is the phrase "the atomic bomb can be made". Editor/Sang Xiaomei

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~