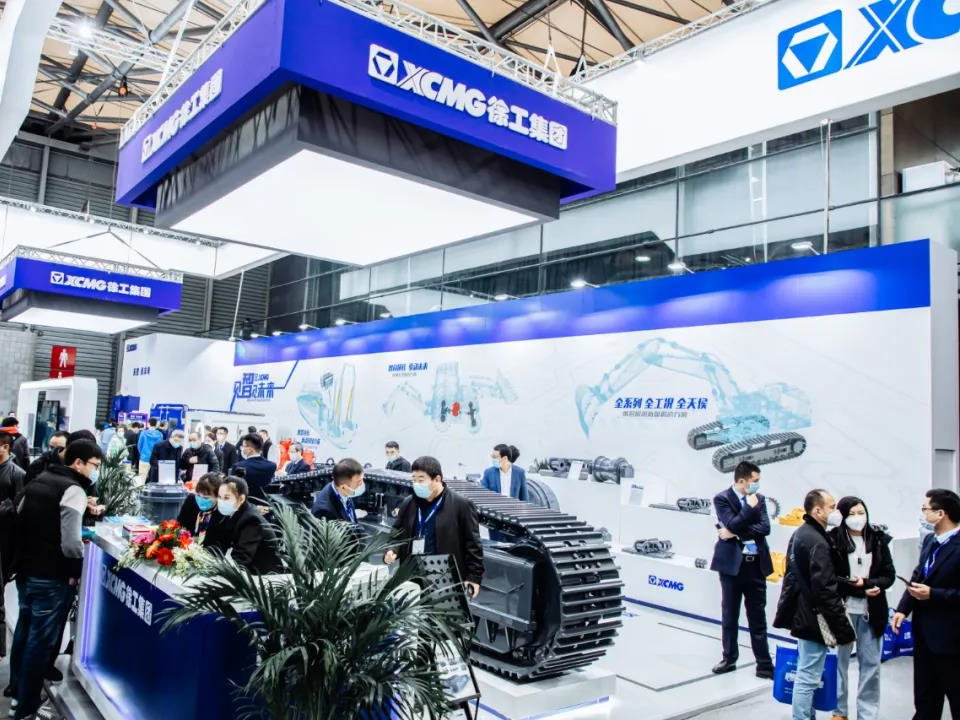

- XCMG carried crawler-type construction machinery chassis products at the 2020 Shanghai Bauma Exhibition

At this Bauma Exhibition, XCMG carries "full range, full working conditions, all-weather" crawler construction machinery chassis products, with key features such as high technology, high reliability, and light weight, providing customers with specialization, customization, and complete sets. Tracked chassis solutions.

Full series, build a new product system

Take the excavator as the core, establish a full range of product systems, and meet the mainstream market demand with strong resource guarantee capabilities.

Crawler chassis products are the key core components of crawler mainframes and are one of the most competitive industries. In the past seven years since its establishment, the compound growth rate of XCMG tracked chassis has been ranked first in the industry. In recent years, in the face of the country’s economic transformation and upgrading and the fluctuations in market demand, it has actively adapted to the new normal, fully aligned with industry benchmarks, and continuously consolidated its product spectrum. And made a major breakthrough in key core technologies.

Among them, the annual output of the complete set of "Four Wheels and One Belt" products with a pitch of 260mm or more ranks first in the industry, and the full-process localization of "Four Wheels and One Belt" products with a pitch of 317 mm has filled the domestic gap. Now it has realized the full coverage of the full range of excavators from 0.8 tons to 200 tons, completed the independent research and development and batch matching of more than 100 crawler chassis products, and has become the backbone of the global crawler chassis industry.

At this exhibition, XCMG brought a 1-ton mini-excavator crawler chassis to the exhibition. This is the smallest tonnage excavator "four-wheel-one belt" independently developed and mass-produced in China. Although it is only 1.3 meters long, its strength cannot be underestimated: XCMG Has fully mastered a number of key core technologies such as forging, heat treatment, and finishing, and adopted fully automatic robot welding lines in the production process to realize the continuous scanning heat treatment of the micro chain track treads, which is more than twice the efficiency of the peers. Customers' high-quality needs.

Looking back at the 2018 Bauma Exhibition, XCMG’s independent research and development of the 200-ton super-large tonnage excavator with independent intellectual property rights has filled the domestic gap. A number of industry-leading technologies and more than ten patents demonstrate XCMG’s independent research and development capabilities.

In the past two years, the "four wheels and one belt" for 200-ton excavators have been put into mining operations, and the reliability is significantly better than imported products, which has won the affirmation and trust of users. With the development of crawler-type construction machinery in the direction of high-end and large-scale, higher requirements have been put forward for the "four wheels and one belt". Research on core technologies based on product reliability and improved working condition adaptability has become the sustainable development of the crawler chassis industry new goal.

Full working conditions, shaping a new competitive landscape

Extensively explore the working conditions of various crawler construction machinery, and provide the best solution for the main engine with strong scientific research and innovation capabilities.

Natural selection, survival of the fittest. To survive in competition, human beings must struggle more; if products want to win in competition, they must have their own core competitiveness.

After several years of hard work, XCMG's crawler chassis products have fully covered the main working conditions of domestic crawler construction machinery. It is the first in the industry to carry out original technology research on crawler chassis multi-body dynamics, product strength and rigidity, which has jumped to the leading domestic level.

Using the industry's first-class lean manufacturing model and quality assurance capabilities, a stable strategic supply system has been established, and a fast and effective industrial chain capability has been formed. The process technology and manufacturing assurance capabilities are at the leading level in the industry, and the product failure rate and reliable life span have reached the leading domestic level. International advanced level.

The national "One Belt One Road" initiative provides a good development environment and a valuable opportunity platform for enterprise development. XCMG Track Chassis Co., Ltd. is firmly confident to face challenges bravely, seize opportunities to seek development, and help customers succeed with high-quality and cost-effective products. The host has participated in the construction of the world's largest coal-to-oil base, Pakistan's aid construction, Indonesia's Yogyakarta airport construction, Longhai Road viaduct, Lanxin Railway and other major domestic and foreign projects, with outstanding performance and invincible performance.

In the face of complex working conditions such as bulldozer pushing and overturning, the "four wheels and one belt" meets the continuous high-load operation with extremely high strength and wear resistance; in the harsh open-pit mine, it is equipped with industry-leading hydraulic motors and walking reducers. The overall chassis of XCMG strongly guarantees the stability of the main machine's walking operation; for the paver and milling machine for road construction, the structure and technology are continuously optimized to ensure the good mechanical properties and surface wear resistance of the "four wheels and one belt".

All-weather, challenging new technological innovation capabilities

Focusing on the typical extreme cold and extreme heat environment, exploring technological peaks with strong research capabilities to meet the individual needs of customers.

Facing the increasingly fierce market competition environment, complex and changeable climatic conditions, as well as the increasingly individualized supporting needs of customers, the "Four Wheels and One Belt" products are facing new challenges in terms of high temperature resistance and extreme cold resistance.

XCMG Crawler Chassis Co., Ltd. aims to reach the top of technology, focus on the market, focus on shortcomings, and overcome many high temperature and extreme cold conditions adaptability design problems such as bolt strength decline and seal failure technology under extreme conditions, and ensure product extremes Reliability of working conditions.

In Antarctica, the coldest part of the earth, XCMG excavators are working in icy and snowy fields, and it is the crawler chassis product independently developed by XCMG that helps the excavator to move forward steadily and tread on the ice. It adopts new structures, new materials and special manufacturing technologies. Even in the face of extreme cold weather of -70℃ to -120℃, it is not afraid.

In the South Jiangsu Steelmaking Plant, the steel grabber supporting XCMG's crawler chassis is cleaning the high-temperature slag, and the temperature in front of the furnace is as high as 200℃; in the North Jiangxi open-pit coal mine, there is sun exposure and coal spontaneous baking underneath. XCMG is resistant to high temperature. Continuous operation of the crawler has won praise from users for its high reliability, high strength and high toughness.

As one of the key basic resources that XCMG's global industrial Mount Everest must master, the core components of the crawler chassis will closely follow the high-quality development requirements of "three highs and one possible", strive to overcome difficulties, continue to innovate and make breakthroughs, and create trustworthy customers. "Full range, all working conditions, all-weather" products help tracked construction machinery at home and abroad to run "acceleration". Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~