- Weichai's engine sales set a new record for sales and became the world's largest engine manufacturer

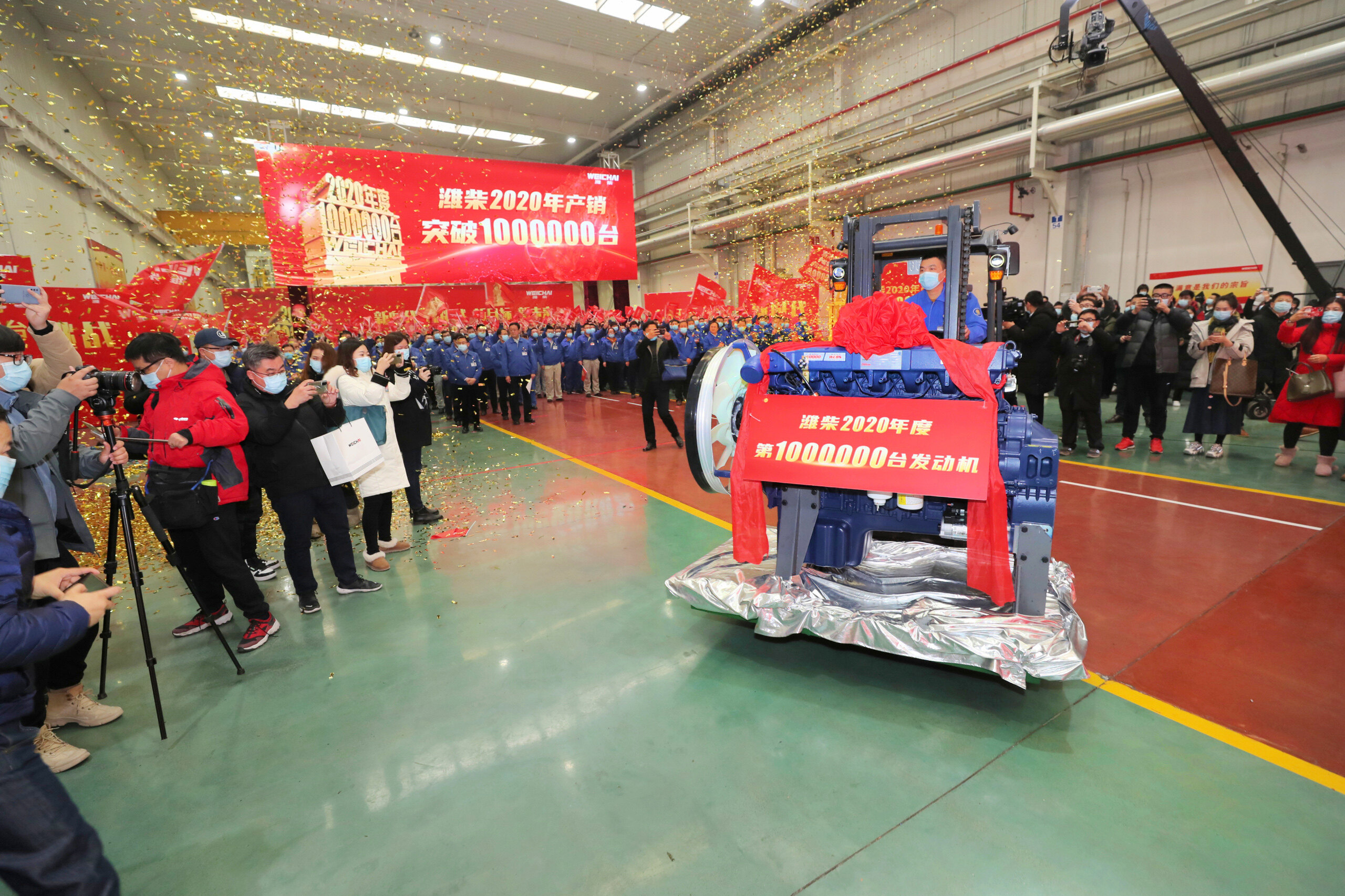

Weichai's 2020 is destined to be extraordinary. Weichai, which is advancing all the way, ushered in a new milestone. At 10 a.m. on December 28, 2020, Weichai held a ceremony in the production workshop of Weifang headquarters, officially announcing that the production and sales of engines in 2020 will exceed 1 million units, making it the world's largest diesel engine industry cluster.

In 2020, Weichai Group will overcome the adverse effects of the global new crown pneumonia epidemic, take the lead in resuming production and seizing market opportunities. The cumulative production and sales of various engines have exceeded 1 million units, an increase of 33% year-on-year, and the total sales of engines will rank first in the world for the first time; Overcoming the decline of 2% and 89% in revenue and profit of overseas European and American companies, the group still maintained a year-on-year growth of 15% in revenue and profit throughout the year. Following the successful release of the world's first commercial diesel engine with a thermal efficiency exceeding 50%, Weichai once again made a strong mark in the history of the world's internal combustion engine industry.

The "big exam" of the epidemic shows the role of state-owned enterprises

At the beginning of 2020, a sudden epidemic has brought a huge impact to the global economy, especially large state-owned enterprises that play a mainstay role in the industrial chain, with large employee groups, difficulty in resuming work, and criss-crossing upstream and downstream supply networks, triggering a move. Throughout the whole body, any "fall" will affect the entire industry chain. As a key enterprise in Shandong's equipment manufacturing industry, Weichai focuses on epidemic prevention and production, gives full play to the political advantages of state-owned enterprises, implements grid-based scientific control, takes the lead in resuming work and production, and drives the rapid recovery of upstream and downstream enterprises in the industry chain, and is handed over in the “big test” of the epidemic Gave an excellent answer sheet.

On the 27th of the twelfth lunar month last year, Weichai issued a general mobilization order to urgently reserve resources by sea, land, air, and at home and abroad. On the third day of the Lunar New Year, Weichai's engine segment began to resume production; on February 5, Shandong took the lead in firing the first shot of full-load production, promptly spurring more than 300 industrial chain partners to resume work and production; in March Weichai made all-out efforts to achieve full production and overproduction ; Entering April, all domestic companies under Weichai have entered a state of overproduction. The production workshops rotate 24 hours a day, workers work overtime and the machines are running non-stop.

The automobile industry chain is the longest. Among the tens of thousands of parts, even the lack of a screw will affect the output. Under the impact of the epidemic, Weichai has bucked the trend and won market opportunities. In particular, the full range of high-end engines in all fields have achieved a "gorgeous counterattack" in 2020. Among them, Weichai's heavy-duty vehicle power sales exceeded 500,000 units throughout the year, and it was firmly established as the global leader in heavy-duty commercial vehicle power; light-duty vehicle power increased by 134% year-on-year, and its industry position rose from sixth to second; construction machinery power More blooms, the annual sales increased by nearly 25% year-on-year, especially in the strategic new market of the excavator industry, all series of models were fully equipped, and the combination of "Weichai Engine + Linde Hydraulics" grew rapidly; agricultural equipment power throughout the year Sales increased by nearly 50% year-on-year. In supporting fields such as tractors and corn harvesters, Weichai's high-horsepower products occupies an absolute dominant position, with a market share of more than 60%. It has become the Weichai brand in the agricultural machinery industry; in the field of high-end large-bore engine , Weichai quickly deployed high-end markets such as data centers and emergency power supplies for mines, and the amount of supporting equipment has been rising steadily, becoming the company's most eye-catching new growth point, and the product structure adjustment has achieved remarkable results.

Driven by innovation, the leading position continues to be stable

Technological innovation is not only the foundation of an enterprise, but also the way for a country to win in international competition. The Fifth Plenary Session of the Nineteenth Central Committee of the Communist Party of China took scientific and technological self-reliance and self-reliance as the support of the national development strategy and placed it first in all planning tasks. A few days ago, the Central Economic Work Conference put forward eight key tasks including strengthening the national strategic scientific and technological strength and enhancing the independent controllability of the industrial chain and supply chain. For more than 20 years, Weichai has been dedicated to its main business, creating a “Weichai Miracle” with a sales revenue increase of 520 times, a compound growth rate of 33%, a profit increase of 1995 times, and a compound growth rate of 41%. Behind this achievement is the majestic force bursting out of "Science and Technology Leading, Innovation Driven". In the traditional business field, Weichai has intensively cultivated its main business and successfully built a pattern of coordinated development of industrial sectors such as powertrain, complete vehicles and intelligent logistics, and continued to leverage its business structure with independent and controllable core technologies and high-end products. Product structure and market structure are transformed and upgraded. On September 16 this year, Weichai released the world's first commercial diesel engine with a thermal efficiency exceeding 50%, setting a new benchmark for the thermal efficiency of global commercial vehicle diesel engines. On November 11, Shaanxi Automobile Heavy-duty Truck Delong X6000 was officially launched. It is equipped with Weichai's diesel engine that has exceeded 50% thermal efficiency, redefining China's high-end smart heavy trucks, marking Weichai's breakthrough of 50% thermal efficiency diesel engine to achieve commercial support. The combination of the two will surely reshape the development pattern of China's heavy truck industry.

Weichai has been deeply involved in the internal combustion engine industry for more than 70 years. It has a solid foundation in the manufacturing and research and development of diesel engines. It has invested more than 30 billion yuan in research and development in 10 years. It has gathered high-end talents from all over the world and continuously launched research on key core technologies, achieving a leap in independent innovation in the diesel engine industry. This type of development has promoted breakthroughs in the core technologies of commercial vehicle powertrains, CVT powertrains, and hydraulic powertrains, complemented China’s core technical shortcomings in these three areas, and promoted China’s diesel engine industry chain to move towards high-end .

In Weichai’s technological landscape, in addition to traditional diesel engines, high-end large-bore engines, fuel cells, control strategies, and intelligent network connections have also "emerged", and have firmly controlled relevant core technologies and successfully built new technologies, The "new moat" of the new format. Especially in the field of new energy, Weichai integrates global resources and builds a new energy powertrain integrating "hybrid power + pure electric + fuel cell", which has ample reserves for seizing the new round of new energy opportunities. The technical strength of the company successfully completed the adjustment of the business structure.

Industrial upgrading, empowering Shandong equipment manufacturing

Weichai has grasped the main business with one hand and the transformation with the other. At the milestone moment when the traditional power has crossed the "million units" mark, the industrial transformation and upgrading has also achieved remarkable results. High-end equipment is one of the "Top Ten Industries" in Shandong Province, and it is also a breakthrough point and development direction for the conversion of new and old kinetic energy. A few days ago, the Shandong Provincial Party Committee issued the "14th Five-Year Plan" and the 2035 long-term goals recommendations, and proposed major breakthroughs in the construction of a strong province with advanced manufacturing. The competitiveness of power equipment and offshore equipment has entered the leading ranks of the country, forming a group of Globally influential industrial clusters, leading companies and well-known brands. As the main undertaker of Shandong's development of the "Top Ten Industries" and the promotion of the conversion of new and old kinetic energy, Weichai has been accelerating the deployment of new business formats and new models, cultivating new kinetic energy and injecting new engines into the high-quality development of Shandong's equipment manufacturing industry in recent years. "New business format" took the lead in landing. In 2020, Weichai's 20,000 sets of fuel cell engine and stack production lines will be completed and put into production, and more than 300 hydrogen fuel cell buses will be successfully promoted in Weifang, Jinan, Liaocheng and Jining, with a cumulative operating mileage of more than 4 million kilometers. At the same time, Weichai is actively playing a leading role and synergizing the group's industrial chain to accelerate the technology research and commercialization of fuel cell heavy-duty truck engines in application scenarios such as urban logistics and port transportation, and explore a new path for the construction of a "hydrogen energy society" in Shandong .

"New Manufacturing" is at the forefront. Intelligent manufacturing is the leading direction for the development of advanced manufacturing. Weichai has continued to accelerate the digital transformation of manufacturing, forming a rapid design-oriented smart R&D system, a smart car networking centered on user experience, and lean-oriented smart manufacturing and product integration. Life cycle intelligent quality management has realized the end-to-end full value chain of the enterprise. In 2020, Weichai was successfully selected as the global "lighthouse factory" selected by the World Economic Forum, marking Weichai's official entry into the global "first phalanx" of intelligent manufacturing. On February 12, 2020, Weichai (Weifang)'s new million-unit digital power industry base took the lead in starting construction, launching the first shot of major projects in the province. The implementation of this project will not only continue to consolidate Weichai’s leading position in traditional advantageous businesses, but also has important demonstration significance for the development of advanced manufacturing in Shandong.

Try the "new model" first. Weichai is not only advancing by leaps and bounds in the front-end market, but also boldly innovating and proactively acting in the terminal market. Focusing on the aftermarket business model innovation, Weichai strives to build "service-oriented manufacturing", innovating service channels, extending the service cycle, and integrating all-element service resources. Under the premise of the advantage of the holding quantity, we will build a full-cycle and full-series aftermarket service system, aim to build a 50 billion-scale aftermarket business, continue to tap the value space of the industry chain, and fully complete the adjustment of product structure, business structure and regional structure. It has made a powerful demonstration and drive for the "model innovation" of Shandong's equipment manufacturing industry.

The new goal spurred new momentum, and the "14th Five-Year Plan" was a grand plan. "During the '14th Five-Year Plan' period, we must unswervingly take the equipment manufacturing industry as the main axis of the province’s economic revitalization, especially in the process of transforming and upgrading traditional equipment manufacturing to high-end equipment manufacturing, fostering the formation of automobiles, high-end agricultural equipment, The three major industrial clusters of high-end construction machinery will create a large number of high-end brands in the industrial chain and make new and greater contributions to the development of Shandong's equipment manufacturing." said Tan Xuguang, Chairman of Weichai Group. Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~