- The smooth rotation of the Chengnan Express Bridge promoted the completion of the Chengdu restoration project

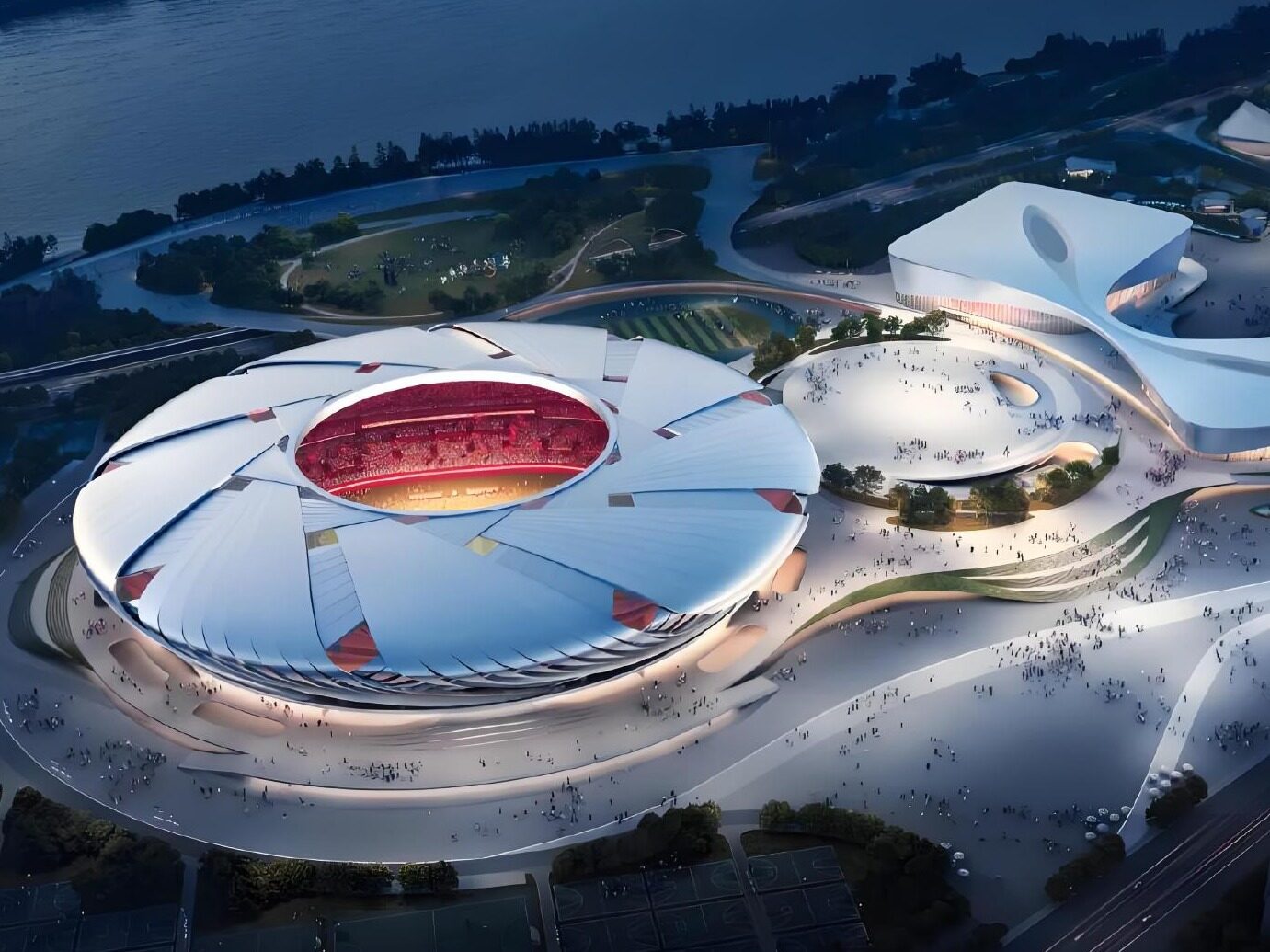

The Chengdu (Du) Nan (Chong) Expressway is currently one of the busiest trunk lines in Sichuan Province, with an average of more than 50 cars passing by every minute. At 0:30 on April 27th, the Chengdu City Ring Ecological Restoration Project, a large-span double-span hyperbolic steel box girder swivel bridge over Chengnan Expressway, undertaken by China Railway Urban Construction Group, successfully completed the synchronous traction swivel. The rotation lasted 120 minutes. The two bridges perfectly completed the difficult "air gymnastics" and successfully realized the zero-error rotation docking.

Greenway construction

The swivel bridge is a key part of the ecological restoration project around the city in Chengdu. It is the first double-span hyperbolic steel box girder bridge that completes the aerial swivel closure of the Jincheng Grade I Greenway. The swivel part is a 162-meter-long steel Box girder curved T structure with a curve radius of 182.6 meters, the top width of the bridge is 7 meters, the bottom width is 4.53 meters, and the height is 2.8 meters. The south side swing bridge is 78 meters long and weighs 189 tons. The north side swing bridge is 84 meters long and weighs 198 meters. Tons, the intersection angle with the axis of the Chengnan Expressway is 88°.

It is understood that the total flow of Chengnan Expressway is close to 70,000 throughout the day. In order not to affect the normal traffic of vehicles and minimize the impact on the high-speed aorta, the bridge turning construction operation was selected at night with low traffic flow. After negotiation and communication with the expressway management department, the expressway was suspended for 3 hours, the fully enclosed operation was implemented, and the construction progress was fully promoted. The difficulty in the construction of the double-span hyperbolic swivel bridge lies in its large span, close to the expressway, and a narrow work site. The steel box girder body is "divided into parts" and decomposed into 4 sections. BIM software is used to draw modeling and adopt "advanced field". The "post-welding and re-assembly" construction process effectively guarantees the progress and quality of the project.

Before the revolving construction, the project technical team set up a special implementation team, organized more than 20 technical briefing meetings, conducted rigorous discussions, plan review, repeated demonstrations and optimization of the technical plan, and strictly controlled each procedure. And on the 24th, a 5-degree pre-rotation test was carried out. According to the predetermined plan, the technical tracking was implemented synchronously, and the traction work was commanded synchronously. The on-site bridge measurement monitoring group, safety protection group, etc., performed the main bridge rotation speed and rotation attitude. Carry out real-time monitoring, accurate inspection of the parameters before the rotation, and real-time adjustment of related parameters, so that each angle can be controlled in place according to the pre-control, to ensure that it is accurate and error-free during the official rotation.

During the turning process, the on-site staff arranged scales and numbers on the turntable of the turning beam, and installed speed sensors and cameras to monitor the turning of the bridge in real time, and effectively adjust the turning speed according to the actual situation on site. The north-south double-span rotating bridge rotates slowly and synchronously at an average speed of 1 meter per minute, the south is rotated clockwise by 109.5°, and the north is rotated counterclockwise by 108.65°, finally achieving precise docking of the two bridges.

Pan Qingjun, the person in charge of the project, said, “The principle of a rotating beam is like pushing a grinding disc. First, a turntable is installed on the bridge pier, and a jack is used to pull the bridge to rotate according to the millimeter-level error standard, and the bridge body built in parallel to the road will be rotated. It is connected with the approach bridge. The key processes of weighing and counterweight before turning, trial turning, and formal turning ensure the smooth turning of the two bridges, laying a foundation for the rapid advancement of greenway construction."

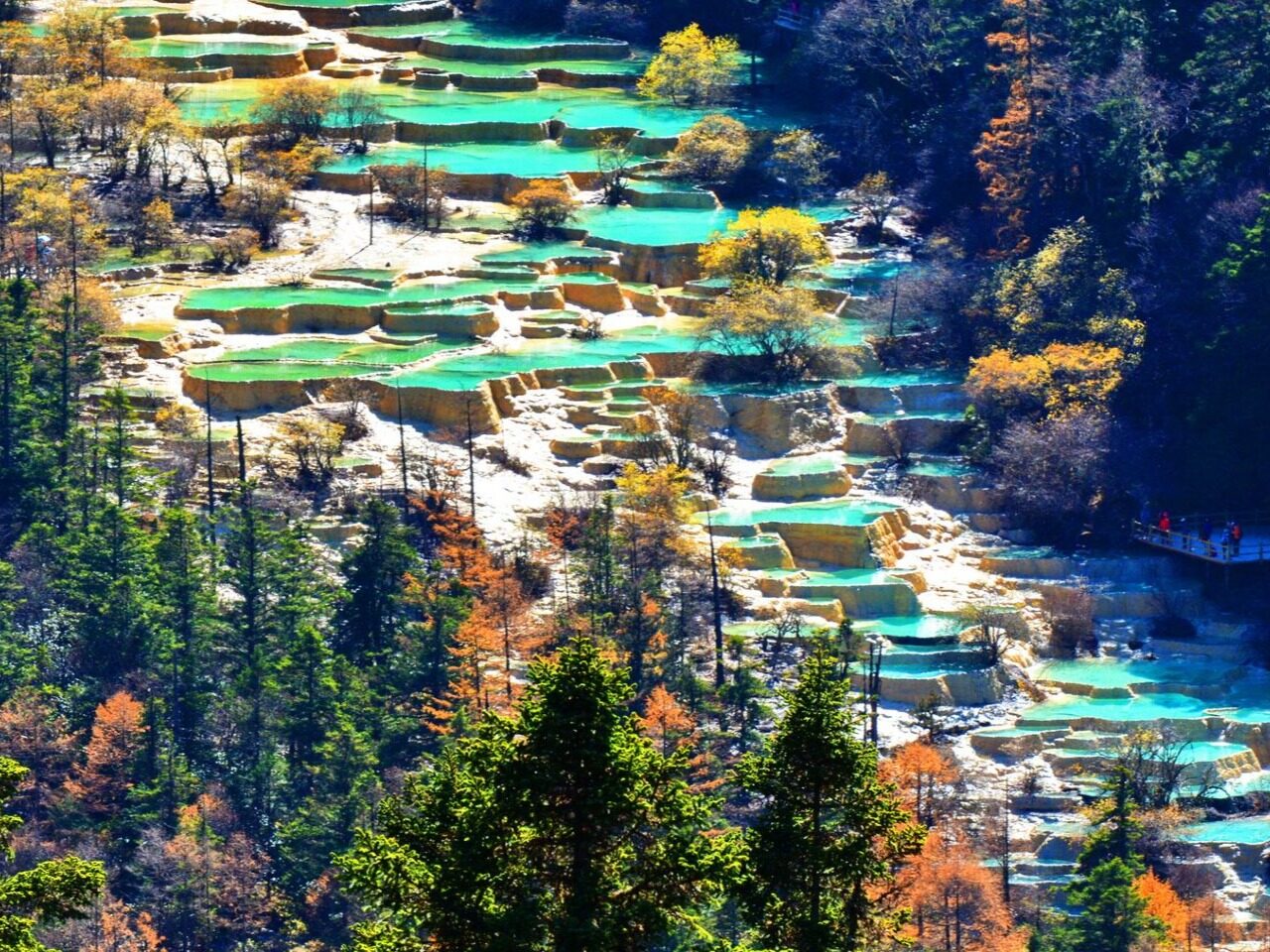

The smooth rotation of the high-speed steel box girder bridge across Chengdu South has effectively promoted the entire line of the ecological restoration project around the city in Chengdu, and has accelerated the design concept of “agriculture as the bottom, roads in series, landscape integration, and sufficient functions” as soon as possible. Realized, the beauty of "Dongtang Xingluo Hundred Water Run City, Xiqu Qianmo Six River Irrigation Capital" was formed. Editor/XuNing、Design/Jishujie

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~