- In the late Qing Dynasty, Li Dengyuan’s "Jade Paintings" showed the process of ancient Chinese jade

The production process of ancient Chinese jade is becoming more and more perfect with the development of social productivity. The process of the jade in the Neolithic Age was relatively simple. Later, due to the use of metal tools such as copper and iron, the process was gradually complicated, and a complete jade production process was formed in the late Qing Dynasty.

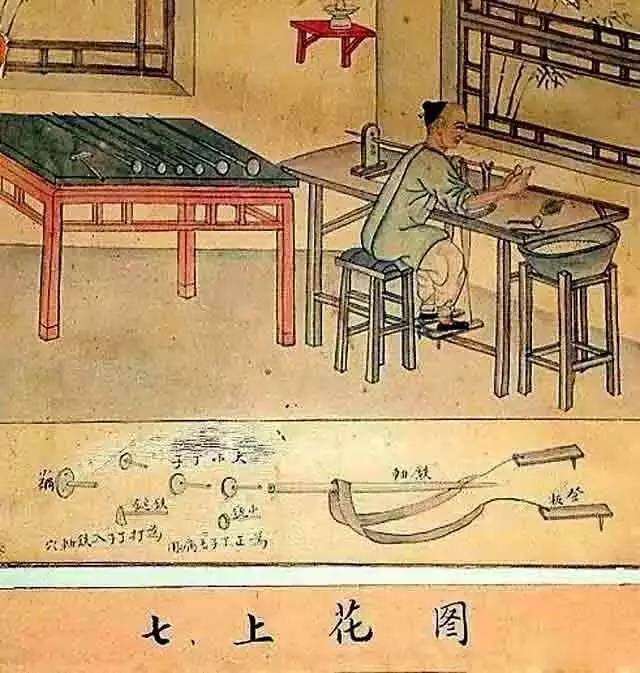

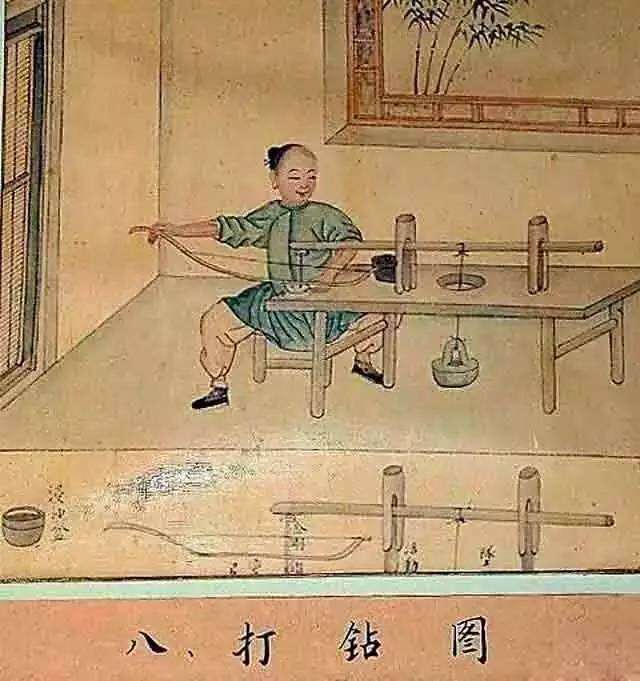

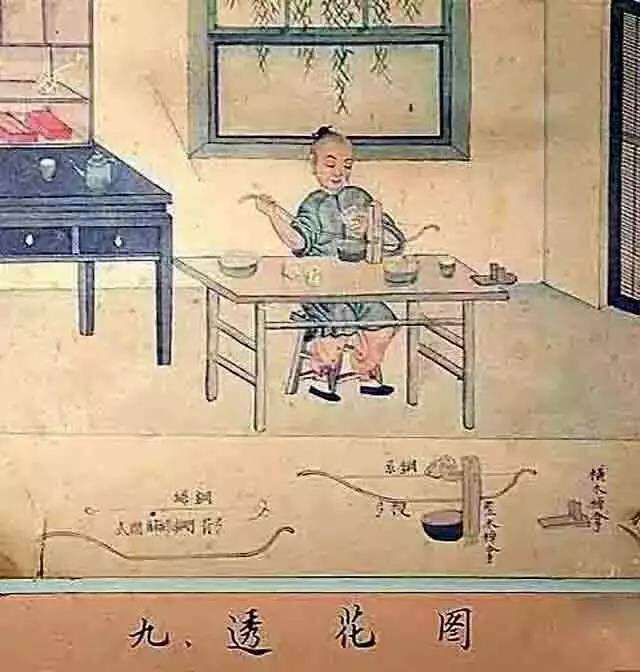

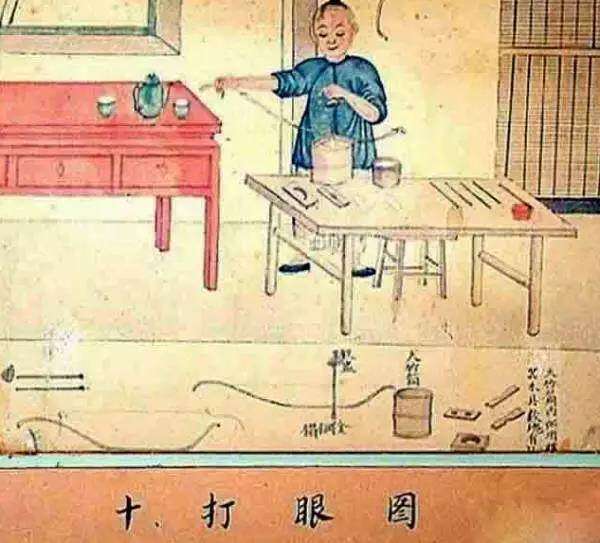

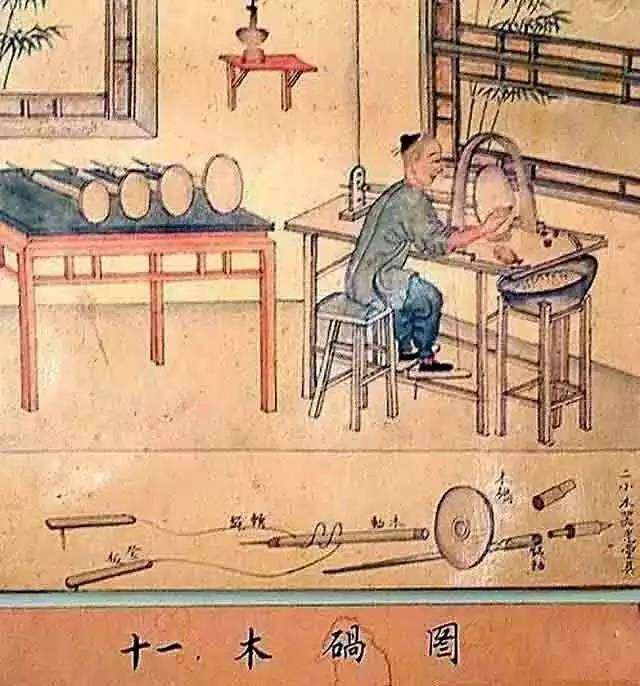

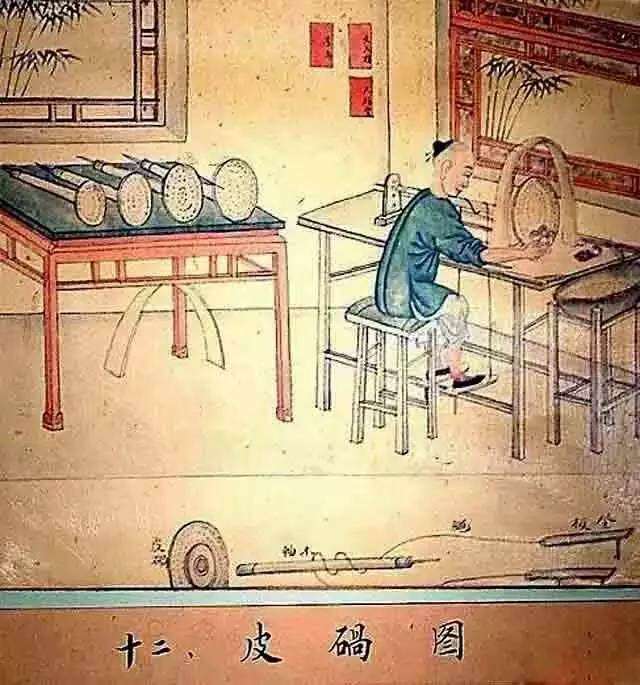

In the late Qing Dynasty, Li Dengyuan’s "Jade Paintings" decomposed the process of ancient Chinese jade into sand, mortar, jade, zha, rushing, honing, smashing, flowering, drilling, translucent, eye-catching, Wood rafts, leather rafts, etc., that is, first to prepare jade sand (sand sand, pulp), then use a saw without serrations (also known as wire drawing) and jade sand to cut the jade material (open jade), and then Cut the jade into a billet (clam) on a wheeled disc with a disc harrow, and then smooth the surface as needed, or with a rotary disc with a thick edge. , honing), or with a reel with a reel, a boring boring machine, or a carousel with a disc-shaped hook (also known as a dicing) On the flower), if you need a silk flower, use a drill to drill (drill), then use a bow and a saw (transparent), and finally polish it, and use a wooden disc to wrap the mortar or cowhide to spin. Polished (wood, leather). A beautiful jade was introduced through such a process.

In the past, the hardness of jade was not enough to honed a part of jade. It relies on the sand between the enamel and the jade, grinding a certain part of the jade bit by bit. The sand used in jade jade is scoured from natural sand. The red sand, black sand, yellow sand and black sand have the highest hardness and can reach 8-9 degrees. The sand and the slurry are processed to the required level of fineness. The sand that has been made into a mortar is placed in a vessel for precipitation, and during the precipitation process, it is finely and naturally layered.

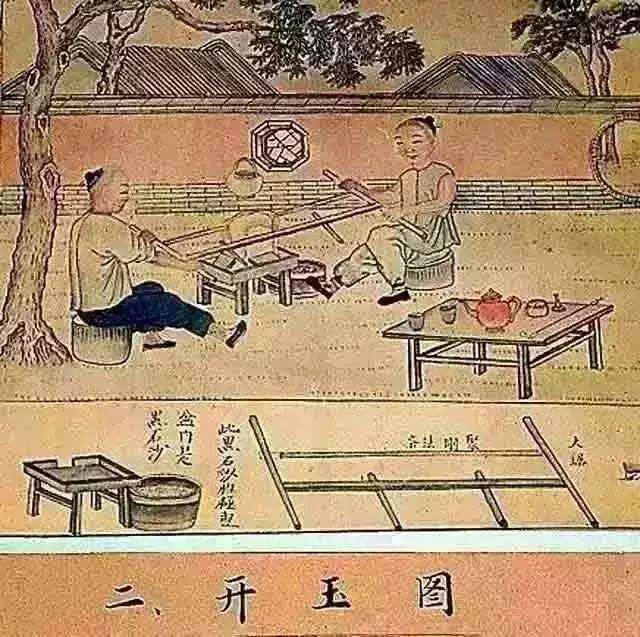

"Open jade map." Decompose a large piece of jade, using a tool similar to a saw. In the past, bamboo boards were used to bend into bows, also known as bows. The picture is more like a saw. The bow string of the open jade is made of wire, and several wires are twisted into twisted strands. When opening jade, add jade sand on the string, and continue to add water, and slowly "grind" the jade material.

"Zhatu map." The main role of the jade is equivalent to "cutting". Cut the jade material, or cut off the part, use a large bow for the large material, use a small bow for the small material, and tie it with a smaller or part.

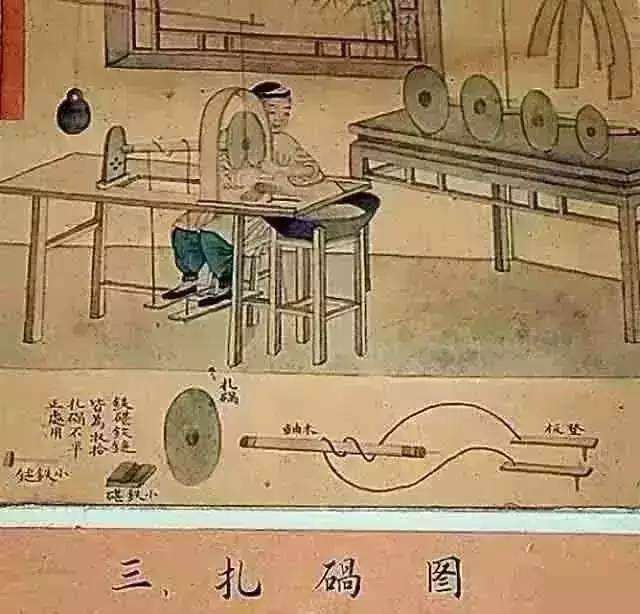

"Crushing the map", the punch is a rough grinding, equivalent to making an embryo.

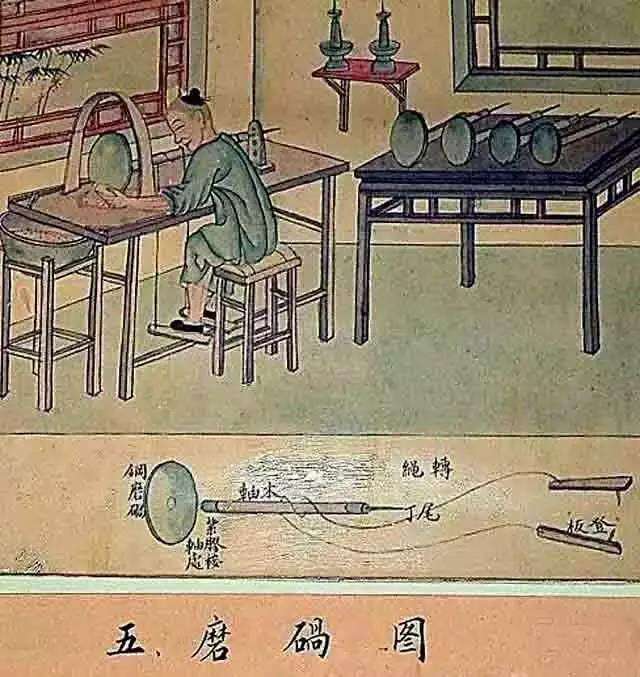

"Grinding map." Relatively flushing is further processing, grinding the details on the basis of the embryo.

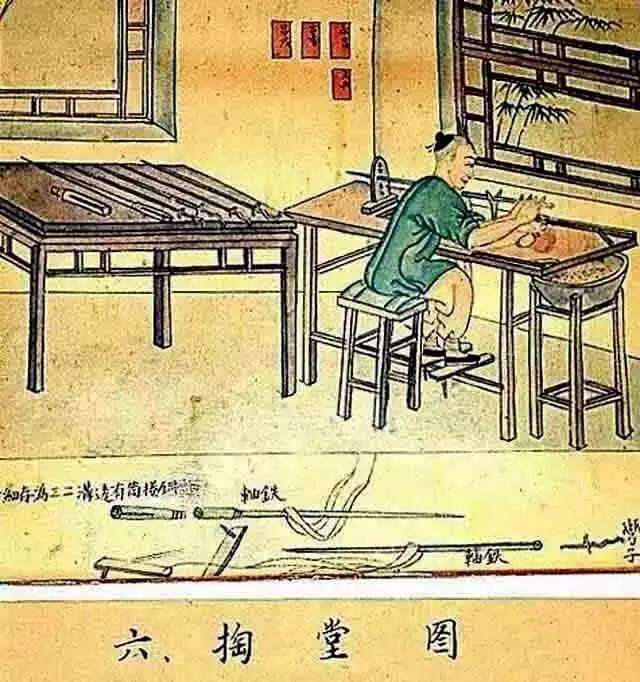

The temple is just like a child. Such as snuff bottles, bottles, bowls, pen holders, cups and other jade, you must be a child. To drill an eye on the jade, then use a special hoe to grind the internal jade.

"Flower on the map." On the grounded objects, honing various patterns. As can be seen from the figure, the enamel used for the flower is smaller and the model number is more.

"Drilling the map." Drilling uses a tubular abrasive to drill a circular groove in the jade. Drill into a certain depth, knock out the center of the circle, you can sleep. There is also a detail in the figure, that is, a heavy object is hung on the crossbar to increase the downward pressure and improve work efficiency.

"Transparent flower map". That is to do relief, hollowing out.

"eye view." Grinding an eye on the jade. This is a special technique for drilling holes that are small and have a fixed shape like snuff bottles, fingers, and mouthpieces. Because this kind of jade is too small, it is not convenient to hold the drill with the hand, so the water is installed in the big bamboo tube, the wooden board is installed on it, the hole is dug in the center of the board, and the shape of the hole and the small jade to be drilled, The shape is the same. Small jade pieces of different shapes should be matched with wood boards with different shapes of holes. The left hand of the jade worker holds the small "iron shovel", and the right hand pulls the "stretching bow". One by one, the iron shovel is repeatedly rotated, and the diamond drill embedded in the lower end of the shovel will drill a hole in the jade.

"Hibiscus map." The hibiscus is a polished enamel, usually made of cucurbits.

"Peel map." The skin is made of cowhide and is used for the final polishing of the jade.

The so-called jade is not awkward. A good handed down jade is made by a variety of procedures, and Xiaobian has sorted out some jade articles handed down in the Qing Dynasty. Please appreciate it!

White jade lotus double-layer box, Qing Emperor Qianlong, with a height of 11.5cm and a maximum width of 11.5cm.

Baiyuxianren Cup, Qing Emperor Qianlong, 9.3cm high, 18.5cm long, 11.5cm in diameter.

Bai Yuyi Zi Sun Pei, Qing Emperor Qianlong, 13.7cm long, 8cm wide and 0.65cm thick.

Qing Palace, 4.8cm high, 14.1cm in diameter, 7cm in diameter.

The style of the artwork is related to the aesthetic orientation of the producer. In the white jade, the gold is staggered with gold and inlaid with red gems, which is extraordinarily luxurious and rich. The instrument has a typical trace of the Durstein style, and the external beauty of the artifact reflects the unique and passionate character of the western nation. Because of its unique artistic charm and exquisite workmanship, the bowl has always been cherished by the Emperor Qianlong since its inception in the year of Emperor Qianlong (1786), and was used as a tool for the royal palace to give tea even during the celebrations. Editor / Zhao Jing

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~