- The builders of China Railway 14th Bureau have completed the task of laying tracks for 420 kilometers under harsh conditions

On July 1, 2021, on the centenary of the great Communist Party of China, the main track laying of the Bazhou section of the Heruo Railway undertaken by China Railway 14th Bureau Group was completed, and the construction of the project achieved a phased victory. When the last pair of steel rails landed steadily on the sleepers, there was enthusiastic applause and cheers. Immediately, all party members faced the party flag, fisted with their right hands, raised their shoulders, solemnly revisited the party oath, and the sonorous oath resounded in Taklimakan. Over the desert.

All party members of the project revisited the party oath at the track laying site

China Railway 14th Bureau undertakes the task of laying the 535km track on the main line of the Bazhou and Hotan area of the Heruo Railway. The builders are exposed to severe heat, cold, and sandstorms under the harsh conditions of no water, no roads, no electricity, no smoke, and occasional mobile phone signals. Frequent tests have completed the 420-kilometer track laying task, interpreting the original mission with practical actions, and fulfilling the oath.

Moving forward at a speed of 2 kilometers a day, spectacular!

"Every day is to lay the rails, wait for the trains, pave the rails, wait for the trains... When the trains come, the workers have to rush to the track laying site, and it takes 8 or 9 hours to shop." Heruo Railway Project Minister Shop Team leader Zhou Yuanguo introduced his daily construction tasks. The track laying construction of the Heruo Railway Project Department extends from Ruoqiang to the direction of Hetian monorail. As the laying mileage continues to increase, it becomes more and more difficult to transport track laying materials.

The long rail transportation train filled with materials starts from the Ruoqiang track laying base and is transported to the track laying site through an engineering line of more than 800 miles. During the transportation process, 10 stations along the line are used to coordinate and avoid operations such as rail welding, major maintenance, and ballast unloading under construction. If you are not lucky, you will have to stand by in severe weather such as sandstorms. The complex traffic scheduling on site makes it difficult for large trains to arrive at the track laying site accurately at the scheduled time. On-site track laying operators have to adjust their work and rest time at any time to meet the needs of on-site construction.

Heruo railway track laying site

In order to ensure the smooth progress of track laying in accordance with the requirements of the nodes, the Heruo Railway Project Department has successively invested 14 power equipment and assembled 4 long rail transport vehicles to increase the frequency of material transportation. At the same time, reasonable allocation of large train loading personnel at the track laying base, implementation of a two-shift system, further accelerate the loading speed, ensure the progress of the construction ahead, use the traffic scheduling system to rationally optimize the large train transportation organization and dispatch, and insert needles to avoid other operations and quickly arrive on the scene. In order to ensure the safety of on-site construction workers, the project department arranged two teams to alternate on duty, take turns to rest, and fight day and night to overcome difficulties such as large cross-interference in construction, long transportation distances, and many sandstorms. The desert was successfully completed at an average speed of 2 kilometers per day. A feat of eight hundred miles of track laying on a single track.

Safety is always on the lookout, keep an eye on it!

"Safety is no small matter, prevent trouble before it happens." This is the code of conduct for every builder, and it is the guarantee of the life safety of all railway builders. The steady progress of the construction of the Heruo Railway is inseparable from the unremitting attitude of all the management personnel of the project department on safety risks and the “hot eye” on-site monitoring and control.

The 535-kilometer track-laying line includes a number of construction activities such as power supply and fire protection, lifting and hoisting, engineering line transportation, and long rail laying in the work area and on-site. The situation on the site is unpredictable, and some hard-to-find risk points are always threatening the construction personnel. Safety. As Changpu team leader Zhou Yuanguo said: "The problems on the scene are often unexpected problems that happen suddenly. Any little mistake may lead to serious consequences and cause unpredictable injuries to on-site workers."

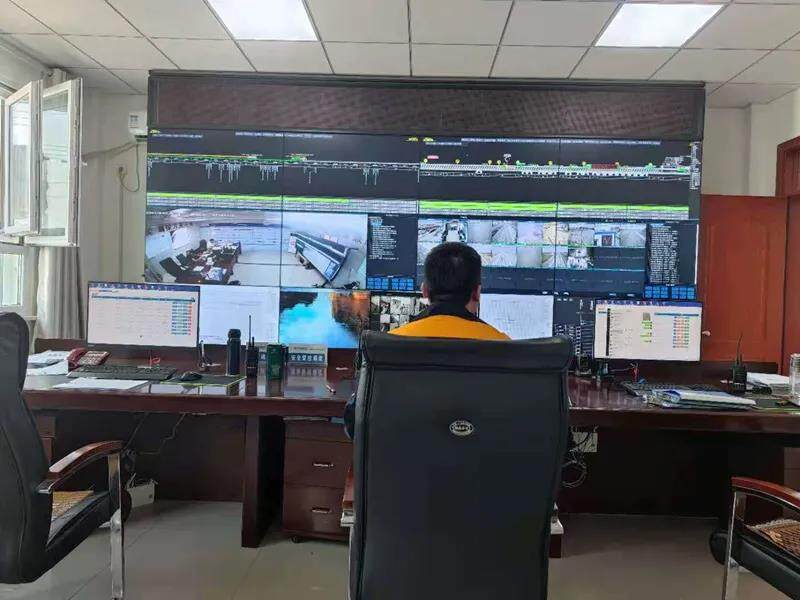

Engineering line safety dispatch system

In order to ensure the safety of on-site construction operations, the project department added "physical defense" management based on the implementation of "civil defense", and introduced a safety dispatch system for engineering lines to realize unified management, unified scheduling, and unified command of engineering lines. The project installs a mobile surveillance dome camera at each construction site to supervise the site operation at all times. Once a dangerous situation is found, the operation can be stopped immediately via radio and mobile phone. Personnel in key positions on the site wear electronic badges, use the engineering line safety dispatch system to realize real-time personnel positioning, use scientific and technological means to strengthen the safety management of the engineering line, supervise the situation of management personnel, and alarm when the locomotive approaches to remind the field operators to leave in time Avoid traffic on the road. At the same time, the project installed GPS locators on the flatbed trolleys and numbered them to keep track of their position information. In response to the risk of slipping the flatbed trolleys, a brake system and an anti-slipping rope were additionally installed.

Electronic badge

The introduction of the safety dispatching system of the engineering line successfully realized the wireless transmission of dispatching instructions, visualized on-site driving monitoring, intelligent plan approval, and timely hazard alarms, which provided a strong technical guarantee for the safety management and control of the engineering line, and realized the "science and technology development". "The goal of safe production.

Engineering line safety dispatching system interface

In response to the safety risks that may exist during the long-distance transportation of large trains, the project department has adopted a series of measures to strengthen the management of the reinforcement measures for large trains. Before the large-scale departure, the large-scale driver, the person in charge of on-site loading operations, and the on-site safety officer will confirm the tripartite. Only after the inspection is firm and there is no risk of scattering, the departure can be carried out. At each station on the way, the stationed personnel will reconfirm the fixed status of the large train to ensure the safety of long-distance transportation of the large train. At the same time, the “double confirmation” system for turnouts is strictly implemented. When all locomotives pass through the turnout or towed, the assistant driver on duty and the station personnel must be responsible for the confirmation. Without the “double confirmation”, entry is strictly prohibited.

For the safety management of special equipment, the project establishes a special equipment dynamic management ledger, strictly ensures that all special equipment operators are certified to work, implements special equipment monthly special inspections and daily maintenance, and arranges special personnel to manage out-of-service equipment to ensure special equipment The equipment is safe to operate. Regarding the safety management of labor personnel, strengthen personnel safety education and training, and improve personnel safety awareness; timely and accurately report construction plans, strengthen on-site safety protection, and deploy safety officers and guards on-site to ensure safe production goals.

The scorching sun and sand in the desert, hold on!

It is currently the hottest stage of the desert. The surface temperature can be as high as 50°C during the day. There is no obstruction on the roadbed 3 meters above the surface. The strong ultraviolet rays burn all creatures who dare to be exposed to the sun. "The most fearful thing now is that Dalley arrives at the scene during the hottest time between 2 pm and 7 pm, and the workers have nowhere to start. No matter where the track-laying machine hits, everything is hot..." The person in charge of the scene, Zuo Cheng, was too wrinkled. Said with an eyebrow.

Not only that, the low shrubs on both sides of the roadbed provide the best habitat for mosquitoes. Every evening, countless mosquitoes follow the lights and leave red packets on the workers. The workers can only endure the itching and do their work carefully. If they don't hold back a few gentle scratches, they will become scars. The rest area of the construction team was temporarily built. The nearby 5000W transformer was difficult to supply for daily use in the living area. The alkaline water from the well was salty and astringent when drinking it, and it could not be drunk for a long time.

Faced with such a difficult environment, the project department actively sought ways to solve the difficulties for the on-site construction personnel. If there are many mosquitoes on the construction site, mosquito repellent toilet water will be distributed to the workers; if the weather is hot, try to stagger the hottest time of the day for track laying. The construction vehicles are equipped with sufficient heatstroke prevention products such as Huoxiangzhengqi water and cooling oil to ensure the safety of the workers. When the transformer is too small, generators are used to generate electricity to ensure that every worker can enjoy the coolness brought by the air conditioner in the hot summer. The water in the desert is hard to swallow, so the project department buys bottled water for drinking to protect the health of the workers.

As the track laying enters the Hotan area, the construction of the Heruo Railway has entered the final sprint stage. In order to ensure the successful completion of the rail link node goal, the project leadership team members have guaranteed on-site inspections at the front line of the construction every day, and regularly hold safety risk briefing meetings to ensure all-round control of construction efficiency, quality and safety. All the staff involved in the construction are united and dedicated to ensure the smooth progress of the remaining construction tasks. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~