- China Railway Construction has stepped up its technical research and independently developed different types of shield machines.

The shield machine is a construction machine specially used for tunnel excavation, and it is a veritable weapon of a great power. China Railway Construction focuses on tunnel construction, rail transit and other fields, increases its efforts to tackle key core technologies, and independently develops different types of shield machines. The leap to "leadership".

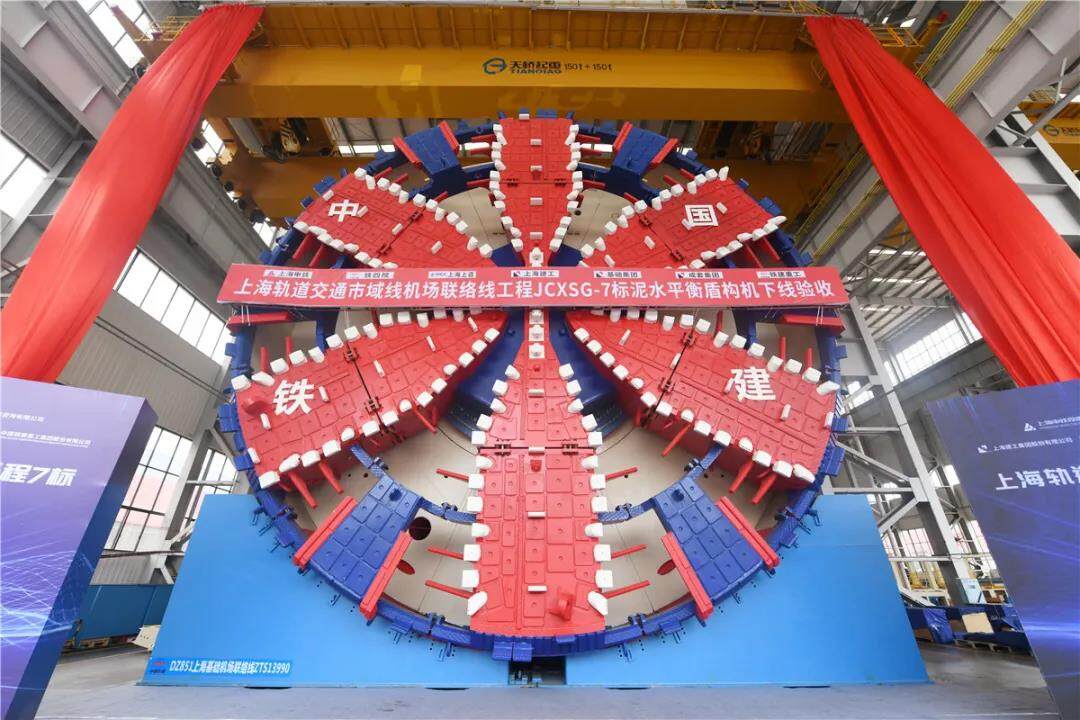

With a diameter of 14.02 meters, on the red and blue circular cutter head, hundreds of white cutter heads form beautiful arcs.

On January 18, 2022, in the Shanghai Rail Transit City Line Airport Contact Line Project, the domestic super-diameter mud-water balance shield machine "Jianxun" drilled forward like a steel dragon.

On July 29, 2021, the super-large diameter shield machine "Jianxun" rolled off the production line in Changsha, Hunan

"The cutter head is composed of an alloy with extremely high hardness. It is 'iron teeth and copper teeth', which can eat soft soil and hard rock." said Fan Ruiqiang, deputy director of the Slurry Shield Institute of Tiejian Heavy Industry Roadheader Research and Design Institute. : "Only the related technology of the cutter head embodies the scientific and technological innovation achievements of the company over the years."

CRCC is the core enterprise of China Railway Construction Corporation Limited in the industrial manufacturing sector. In recent years, China Railway Construction has focused on tunnel construction, rail transit and other fields, and has stepped up efforts to tackle key core technologies. During the "Thirteenth Five-Year Plan" period, CRCC won 17 national science and technology awards, added 14,389 authorized patents, added 4 national innovation platforms, and newly hosted 8 national scientific research projects and 26 subjects.

R & D according to local conditions

Shield machine is a construction machine specially used for tunnel excavation. It is widely used in the field of major infrastructure construction. Because of its super ability to cut through mountains and burrows, it enjoys the reputation of "underground dragon" and "steel pangolin".

The world's largest high-end underground engineering equipment manufacturing base--Tiejian Heavy Industry Changsha Second Industrial Park

How does such a heavy tool work? When the shield machine moves forward, it uses the cutter head to crush the soil and rocks, "eat" it into the stomach, and then transport it to the rear of the fuselage through a special pipeline for discharge. At the same time, through grouting and segment lining, the dug tunnels and tunnels are fixed to form a permanent structure. "Shield" and "Construction" are carried out step by step, one-stop operation.

"A large shield machine weighs more than 3,000 tons and has more than 30,000 parts. It involves many disciplines such as electrical, optics, mechanics, civil engineering, and machinery, and the manufacturing process is complex." Fan Ruiqiang said.

The geological conditions, tunnel size and construction environment faced by different engineering projects are very different, and the requirements for equipment selection are different. Therefore, the shield machine cannot be mass-produced, and it is necessary to develop and tailor products according to local conditions. This also means that each shield machine is "full of personality".

The "Jianxun" is mainly used for the Shanghai Rail Transit City Line Airport Contact Line Project. The tie line passes through important buildings such as rail transit, municipal highways, bridges, etc., which requires higher precision of surface settlement control and environmental protection. When designing the segment lining technology, the R&D team used the overall prefabricated assembly process for the first time to construct the large arc-shaped blocks at the bottom of the tunnel, instead of the traditional cast-in-place method on both sides of the box culvert, to improve the overall construction speed of the tunnel and ensure the quality of the tunnel.

In July 2017, 5 domestic shield machines went to Europe for the first time. Facing the ultra-low temperature construction environment, Tiejian Heavy Industry has developed a main drive that can withstand a low temperature of minus 30 degrees Celsius, and added auxiliary heating systems such as hydraulic pump stations and frequency converters. "Industrial product design usually considers heat dissipation, but this time we added a heating device and an online temperature monitoring system to the shield machine, so that the two systems are perfectly compatible." said Sun Xuefeng, chief designer of the five shield machines. The team repeatedly deduced calculations and thermodynamic simulations, and drew more than 800 system schematics and structural drawings, and finally ensured that the hydraulic oil in the fuel tank was heated up reasonably without affecting the performance of the hydraulic oil.

On June 11, 2018, the first "Polina" shield machine adapted to the extremely cold construction environment was successfully launched, marking the first time that China's high-end subway tunnel construction equipment was put into use in Europe

After years of hard work, in response to different types of construction scenarios such as "super harsh natural environment, super risk geological conditions, super conventional long tunnels", Tiejian Heavy Industry has developed one by one the most important weapons of the country with "unique skills", which are among the best in the industry. leading position.

Overcome the core technology

Accompanied by the roar of machines, in the construction of the reconstruction project of the East Sixth Ring Road in Beijing, the "Jinghua" developed by Tiejian Heavy Industry Co., Ltd. is carrying out an underground journey. This shield machine with the largest diameter developed in China so far has an excavation diameter of 16 meters, a length of 150 meters and a total weight of 4,300 tons. On its cutter head, there are nearly 400 carbide tips, which are as hard as diamond.

But no matter how hard the cutter head is, it will wear out. Ji Zhiyong, vice president of the Roadheader Research and Design Institute of China Railway Construction Heavy Industry, introduced that the place where the shield machine operates is often dozens of meters underground. In the past, only the method of tool change under pressure was adopted, that is, the professional construction personnel went to the back of the cutter head to manually replace the cutter heads one by one. The feeling of being under pressure is like diving in the deep sea. The human body needs to bear the corresponding pressure, which has a certain risk factor. Therefore, in order to ensure the safety of construction workers, sufficient preparations must be made before the tool change under pressure is carried out, and a stable working environment must be established. "That is to say, in the past, every 200 meters of excavation by the shield machine required a week of 'dressing'." Ji Zhiyong said, for this reason, CRCC and Central South University and other universities have cooperated to build a basic technology and application research test platform This provincial scientific and technological innovation platform has developed the atmospheric pressure tool change technology, which greatly improves the tool change efficiency. "Nowadays, the staff gets into the box behind the cutter head, pulls the cutter head back into the box, and replaces it directly after the pressure is released. It only takes 40 to 50 minutes to change the cutter." Ji Zhiyong said.

"In the past, the cutterhead tool relied on imports for a long time, which was not only expensive, but also uncontrollable in delivery time. Now, we continuously test the performance and data on the test platform, and design the shield machine tool suitable for different geological structures, which realizes the 'neck stuck' 'Technical breakthrough.' said Liao Jinjun, president of the Iron Construction Heavy Industry Science and Technology Development Research Institute, at present, various types of shield cutting tools, including extremely hard rock hob, have been completely localized.

The largest domestic diameter shield machine "Jinghua" shines in the national "13th Five-Year" scientific and technological innovation achievement exhibition, and is inspected by the leaders of the party and state

CRCC continuously strengthens the construction of scientific and technological innovation platform. At present, the whole system has 23 national-level scientific and technological innovation platforms and 122 provincial and ministerial-level scientific and technological innovation platforms. During the "Thirteenth Five-Year Plan" period, CRCC undertook and participated in more than 30 national-level scientific and technological projects in response to national strategies, major projects and general market needs, focused on over 100 key core technologies, and achieved innovative breakthroughs in "stuck neck" technology. and part of the lead.

From supporting role to protagonist

On the huge circular cutter head, a giant panda with tender bamboo in its arms occupies the "C position"... This is the "Splendid" shield machine known by netizens as "the most adorable big country and heavy weapon", and it is also a domestically produced shield machine. The pressure-balanced shield machine is participating in the construction of the Jinxiu Tunnel on the Chengdu (Du) Zi (Gong) high-speed railway. Its biggest feature is its high pressure bearing capacity.

It turns out that the Jinxiu Tunnel has "different depths", the minimum thickness of the soil cover is less than 8 meters, and the maximum buried depth is 60 meters. In order to cope with the complex situation of shallow overburden and multiple structures on the ground along the line, the R&D team added 23 advanced grouting holes and 28 radial injection ports for the shield machine. The surrounding soil can be grouted and strengthened in advance, and the supporting medium can be injected radially. , effectively control the ground subsidence and ensure that the ground buildings are not affected.

"Faced with extremely high water and soil pressure, 'Jinxiu' adopts polyurethane sealing technology with high pressure bearing capacity, which can withstand 10 bar water and soil pressure, which is equivalent to supporting the weight of 5 adults with an egg." Tiejian Heavy Industry Excavation Zhong Qing, an engineer at the Earth Pressure Shield Institute of the China Machinery Research and Design Institute, said.

At the same time, "Splendid" is the largest diameter earth pressure balance shield machine with completely independent intellectual property rights developed by China so far, which further consolidates the independent and controllable capability of domestic tunneling technology and equipment.

Going back more than 10 years ago, shield machine technology has been monopolized by foreign countries for a long time. "Foreign brand" shield machines have almost occupied the domestic market, with high prices. In 2010, CRCC developed the first composite earth pressure balance shield machine made in China, and the localization rate of the equipment reached 87%. This major breakthrough forced the foreign shield machine with an average price of 150 million yuan to reduce the price by 30%.

After more than 10 years of development, the domestic brand shield machine has a market share of more than 90% in China. The domestic underground engineering equipment enterprises represented by CRCC, the technology has changed from following to the leading part, and the market share has changed from supporting role to leading role.

However, there are still some problems to be overcome in the innovation process. Liu Feixiang, Secretary of the Party Committee and Chairman of CRCC, introduced that every link in the supply chain of the industrial chain is crucial, and only a stable supply chain can ensure production and supply.

"Our primary task is to carry out the independent innovation of the industrial chain to the end, and adhere to the differentiated and high-end industrial product strategy." Liu Feixiang said that in product development, domestic enterprises should further improve the product type spectrum to meet different scenarios in subdivisions. It is necessary to strengthen the research on common technologies in the industry, actively participate in the formulation and revision of international standards, and form a technical standard system dominated by independent intellectual property rights in key areas.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~